Chapter 1: Introduction, Overview and Summary

Questions you may have coming in:

- How do I determine what is needed? Keep reading!

- What vehicles are compatible? Hardware will work with all 2004 and older Ford vehicles with a J3 port, depending on software support.

- What are the capabilities of Moates hardware? Realtime tuning, logging live data, burning chips, switching between multiple programs

- What hardware and software options are available, and at what cost? Keep reading!

- How do I learn to tune EEC? What learning resources are available? Keep reading! We’ll provide references.

Vehicle Compatibility

- Hardware is compatible with all year/model Ford vehicles that have a J3 port. This generally covers 86-2004 model years.

- If you already have a binary file (bin) or hex file (hex) that is tuned for your vehicle. you can use one of our chips.

- If you need to make changes (tune) to get your vehicle where you want it, you are limited by software support.

- Some ECMs are simply not supported in software that works with our hardware because of lack of definition information.

- It’s important to check for software support before purchase. If you have an uncommon vehicle (for example, a 1995 Festiva) you may be out of luck with our products.

- We need certain information to tell if your vehicle is supported. (click) Email us to check before purchase!

Overview of Tuning Process

- Determine your target vehicle boxcode and strategy.

- The Boxcode is typically a 3 or 4-digit letter/number code on the EEC computer. ( ‘A9L’ or ‘T4M0’ for example) This represents a calibration for a particular engine/transmission using a particular strategy.

- A Strategy is the set of procedures that the ECM follows to run an engine. Combined with a calbration, this determines how the engine will operate.

- The strategy will determine things like whether a MAF or MAP sensor is used, how spark and fuel are calculated, how idle is controlled, etc.

- Each strategy needs a definition (or ‘def’) to work. The definition tells the software how to interpret the binary and display it in a format you can understand with tables and real-world values.

- For instance, the A9L boxcode, belongs to the GUFB strategy. The A3M boxcode also belongs to the GUFB strategy. You can change a bunch of parameters on a A3M computer and have it run 100% identical to a A9L computer.

- Review your software options in terms of availability.

- First: figure out which software supports your box code. Support varies from package to package. Check with each software vendor for the most up-to-date supported options.

- Next: download software and install it. You can check out the interface and features at this time without paying for anything.

- Finally: After you have found a software package with an interface that you like which supports your strategy, go to our web store to purchase. You will need to have already installed software prior to purchasing in order to provide us with information to license it.

- Determine your tuning needs to guide your purchases.

- Do you just need to burn chips?

- Do you want to be able to make changes while the vehicle is running? (emulation)

- Do you want to be able to log vehicle parameters while the engine is running? (datalogging)

- Do you want a more accurate measure of the air/fuel mixture? (buy a wideband)

- Decide what capabilities you need and then purchase hardware as appropriate.

- Install hardware.

- Clean that J3 port PROPERLY!

- To clean the J3 port, you generally must remove the case from the ECM, gently rub the J3 port with Scotchbrite or a mildly abrasive kitchen scrubber. (‘mildly’ is important – you do NOT want to rub hard enough to remove the copper traces from the circuit board!) A final clean with brake clean, starting fluid or another mild solvent doesn’t hurt. A properly cleaned J3 port will have a very, very slight crosshatch visible on the ‘fingers’ of the connector.

- Golden rule: ALWAYS TAKE THE KEYS OUT OF THE IGNITION (CAR OFF!!!) WHEN INSERTING OR REMOVING THINGS ON THE J3 PORT. Failure to do so can result in a fried ECM, fried chip/QuarterHorse or both.

- Install USB drivers

- The same USB drivers are used for all Ford products

- USB driver is a free download from the webstore, it comes with config instructions. (download)

- If you need more visual directions, there is an install guide available on the Moates support site.

- If you have trouble with the install, there is troubleshooting guide available on the Moates support site.

- Setup software and perform initial configuration

- Establish communications, check settings – this procedure will vary depending on software package you are using.

- Select the appropriate strategy for your box code and load any appropriate definition files.

- Program hardware with a calibration to serve as a starting point. A stock tune with a few key parameters modified to suit the vehicle at hand is great. You’re just looking for something good enough to get the car to fire and (hopefully) idle.

- If you are datalogging, select and configure datalogging payload matrix (PIDs) – i.e. what you’re interested in monitoring.

- Gather performance data, analyze it, and make changes toward an optimized result.

- Parameters are gradually adjusted to achieve desired targets.

- This is an iterative process, where adjustments are made and the results are evaluated followed by further adjustments.

- Please see our subsequent chapters on Ford Tuning (available separately).

- Basic Tuning Techniques and Common Examples

- Advanced Tuning and Tricky Combinations

Chapter 2: Hardware Selection and Installation

Several types of hardware are available and needed depending on desired functionality.

Laptop PC

- Windows XP/Vista/7 are all compatible with the Ford tuning software.

- Something 5 years old or newer is recommended (no old 486 machines!).

- Internet access is recommended to facilitate licensing and software installations.

- USB ports (at least 1) are required. All needed cables are included with the hardware.

- If logging wideband, a serial-to-USB converter may be needed. ($37 on our webstore – link)

F3 Chip modules

- These modules install onto the J3 port of the EEC box.

- One per vehicle, $60 per unit – link.

- J3 port MUST be thoroughly cleaned, both sides, before installation!

- Disassemble case, scrape off coating with non-metallic scraper or fingernail.

- Clean both sides with Scotchbrite, not sandpaper.

- Don’t be too rough, just polish it to a nice crosshatch, not down to the copper.

- Clean with paper towel and alcohol or toluene.

- Two-position switch capable with user-added toggle. Directions for switching are on support site. (link)

- Reprogrammable many times using Jaybird.

Jaybird mini-USB chip reader/writer

- Small size, low cost, $75 – link.

- Allows reading and writing of the F3 modules.

- No datalogging or emulation with the Jaybird. No EEC box reading. Most basic chip programmer available.

Quarterhorse Realtime Emulator and Datalogger

- Hardware unit is $249 – link. All cabling is included, along with ferrite shields and USB bulkhead connections.

- Optional rotary switch ($30 – link) can be used to select from several different programs on the device, switching on-the-fly. Works for EECIV ONLY.

- Fits onto J3 port like a chip module – port MUST be clean as with F3 modules.

- On some early EEC boxes, several components will need to be gently bent out of the way for clearance during installation.

- The Quarterhorse is an integrated unit that can do several things:

- Realtime Emulation

- Changes in the calibration take effect immediately while engine is running.

- No disturbance in engine operation or communications.

- Changes in software are synchronized on the Quarterhorse.

- Datalogging

- Requires special definition file with ‘patch code’ written for the QuarterHorse, allowing RAM on the EEC to be shadowed onto the Quarterhorse.

- Unprecedented access to variables and sensor values through the QuarterHorse without additional datalogging hardware.

- Logging rates in excess of 5 kHz possible. Most software logs around 20 Hz, which is great for tuning.

- EEC Reading

- EEC must be installed and powered in-vehicle with QH installed.

- You can read the tune from the EEC box and save it to file.

- This can be done with a stock EEC to acquire the base calibration.

- You will be able to harvest the active calibration that has been programmed with a flash programmer this way.

- Realtime Emulation

Burn2 with F2A and F2E adapters

- The Burn2 ($85 – link) is a general purpose chip programmer that can be used for many different devices.

- When used with the F2A adapter ($10 – link), it can be used to read/write F3 modules.

- If the F2E adapter is added (another $10 – link), you will be able to read EEC boxes.

- No emulation or datalogging – this is a simple chip programmer only.

- This hardware combination is best suited for people that plan to tune vehicles from many different manufacturers. If you plan on tuning exclusively Fords, consider the Jaybird as a less expensive alternative.

F8 chip module with Destiny programmer

- No emulation or datalogging – this is a simple chip with switchable tunes.

- Available exclusively through our distributor DP Tuner

- The $165 F8 module holds 8 switchable tunes and can be reprogrammed in-vehicle without removing the chip from the EEC!

- The $150 Destiny programmer is used with a 4-pin switch cable while F8 module stays installed on EEC.

- Once programmed, the $30 rotary switch can optionally be connected as a calibration selector.

Wideband O2 Sensor and Controller

- Used to sense your engine’s Air-Fuel ratio through exhaust gas analysis.

- Units such as the Innovate DB-Red LC1 Gauge Kit /w/ O2 ($209 – link) are very affordable.

- Software (discussed separately here) supports direct logging of the Innovate device data using a serial interface. This is the preferred method of logging wideband data because it avoids all the pitfalls of using analog signals.

- Analog outputs from the wideband (such as the LC1) can be connected directly to the EEC in some cases (unused EGR pin on A9L for example).

- Wideband O2 readings critical for tuning fueling parameters.

Chapter 3: Software Selection, Installation, and Licensing

Several different software packages currently work with our hardware. Cost varies considerably considerably from package to package along with capabilities. Each software package also has its own unique flavor of interface – you will probably like one better than another. Luckily, you can download and check them out prior to purchase. Also remember that support for various box codes / strategies varies considerably from package to package. It is important to investigate not just whether there is ANY support for a particular strategy but whether the items you require to tune your vehicle are supported – definition files vary considerably from software to software. Fortunately, the availability of ‘trial’ versions makes it possible to ensure you to find a software package that fits your needs without having to purchase each one.

Binary Editor ( http://www.eecanalyzer.net )

- Written by Clint Garrity.

- Currently has the largest user base.

- Cost is $80 for the base application which is registered to a specific PC.

- Includes many of the most common and popular definitions (GUFB, etc) with no additional cost. ( this list has almost all the “free” definitions along with some pay defs )

- Other ‘premium’ encoded definitions available at extra cost ($50-150+) from the definition author.

- Tends to benefit from a faster/newer laptop. Code is a bit heavy, so older PCs are taxed. Think 2Ghz P4 / 512Mb ram realistic minimum.

- Includes EEC reading, chip reading and burning, datalogging, and emulation capabilities when used with the appropriate hardware.

- Also includes logging for wideband (Innovate, PLX, etc).

- Also includes optional support for standalone dataloggers, J2534 interfaces.

- Companion software EEC Analyzer is available for an additional $50. Not necessary, but it helps with data interpretation.

- Licensing occurs after you install the software from the available downloads, through a menu item within the BE and EA software programs.

- Both BE and EA licenses can be purchased from the webstore with information from the program. See webstore product page for further instructions.

EEC Editor ( http://www.moates.net )

- Written by Paul Booth.

- Fairly lightweight software – does not require a very fast PC to work well.

- Cost ranges from $20-65 for each strategy depending on options.

- EEC-IV is $20 for editing DEF (emulation and chip burning) plus $25 for datalogging (DLM) .

- EEC-V is $10 more ($30+$35).

- In order to have a comprehensive tuning solution for a typical fox body Mustang, you would need to order the GUFB def ($20) and the GUFB DLM ($25) along with a QuarterHorse. This would allow you to tune any number of vehicles using the A9L, A3M, etc. processor codes. You can also burn chips with the Jaybird/BURN2+F2A for any strategies you have purchased.

- Includes logging for Innovate Wideband (LC1, LM1, etc) at no additional charge.

- List of available supported strategies is listed on the webstore.

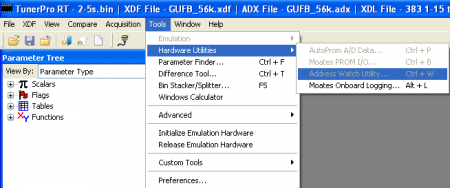

TunerPro RT v5 ( http://www.tunerpro.net )

- Written by Mark Mansur.

- Software license is optional (nag screen) but encouraged for $30.

- Editing portion of software *extremely* lightweight – can run well on older PCs. Parts of logging engine considerably more demanding.

- Many definitions are available for editing only, see Tunerpro.net and our website for details.

- Editing, chip burning and emulation are supported by TPRT V4 and TPRT V5.

- Datalogging using the QuarterHorse is supported by TunerPro RT V5 via new the ADX format. See here for updated definitions.

- QuarterHorse vehicle support is very limited compared to other software, but some of the most popular ones (GUFB CBAZA etc) are well-developed and available at time of writing (December 2010)

Flash & Burn Interface ( Moates/TunerPro )

- This is a low-level utility for reading and writing F3 chip modules using Jaybird or BURN1/BURN2 + F2A

- Capable of reading EEC boxes using BURN2+F2A+F2E. Does not work with QuarterHorse

- If you have a raw binary file ( bin ) you can use Flash n Burn to program a F3 chip module

- No cost, can be downloaded from the webstore.

F8 Destiny Utility ( http://www.moates.net )

- For use with a Destiny and F8 multi-position in-situ chip module.

- Allows easy management of stacks of tunes on the module with PC-based selection.

- No cost, can be downloaded from the webstore.

USB Driver ( Moates.net / FTDI )

- Needed to allow PC to communicate with the USB hardware (Quarterhorse, Jaybird, BURN2, etc).

- In many cases, working drivers will be detected by Windows via plug n play.

- If you need more visual directions, there is an install guide available on the Moates support site.

- If you have trouble with the install, there is troubleshooting guide available on the Moates support site.

Chapter 4: Suggested Techniques for Effective Calibration of EEC Systems

Vehicle Inspection and Preparation

- CRITICAL part of the tuning process. Start here, really. If you fail here, you will never succeed.

- Several areas of the vehicle should always be analyzed before you begin the effort.

- Smoking – learn to identify fuel (black) vs. oil (grey-blue) vs. coolant (white/sweet smelling). You cannot fix oil smoke or coolant smoke with a tune.

- Compression – you should have all cylinders within 10% compression of each other. If smoking, damage to old spark plugs or general appearances make you suspicious of the motor’s health, check it before you start. It’s a lot easier to deal with a motor with poor compression BEFORE you beat the snot out of it in the course of tuning it. Many people skip this but it is something to think about because a motor that is already hurt is very likely to blow up or experience a catastrophic failure during tuning.

- Check base timing, adjust as needed. (all vehicles with a distributor)

- Evaluate TPS voltage. Minimum/maximum values should be within acceptable limits. Check for reversed wires – voltage should increase as throttle opens.

- Look at MAF intake routing, make sure there are no obvious vacuum / intake leaks between the MAF and the intake valves. Think cracked/split/loose hoses, bad gaskets, open ports, dry rotted couplers, hoses connected both before and after the MAF, …

- O2 sensors should be operational without any exhaust leaks before the sensors. For some reason, cut and soldered “extensions” for long tube headers often cause problems. Plug and play extenders are *highly* recommended. If you know that you do not have proper stock O2 sensors, REMEMBER TO TURN OFF O2 FEEDBACK!!!

- If you are using a wideband sensor, you need to make sure there are no exhaust leaks before the wideband. Flex tubing, poor joints between headers- midpipes and cracks in tubing can all create havoc.

- If applicable, pay attention to which bank the wideband is installed in – bank-bank differences can be a powerful diagnostic tool. Pay attention to how far the wideband is from the engine’s exhaust ports – there is always some lag between combustion events and measurement. When things are changing quickly, this is critical.

- Widebands need calibrated periodically, generally in free air. Wideband sensors need replaced periodically. Leaded fuel kills them very quickly. Proper care and feeding of widebands is crucial to their effectiveness.

- Be aware of catalytic converters. Always tap them (GENTLY) and listen for suspicious noises that would indicate a catalytic converter that is degrading. Clogged cats can rob literally hundreds of horsepower. It is possible to place a wideband sensor AFTER a catalytic converter but remember that the cat will very slightly skew readings.

- Make sure you have enough fuel pump and injectors for the power level you are looking for. For a V8, “Injector size in #/hr * 14 = max hp” is a crude rule of thumb. There are tons of injector calculators to be found if you want a better idea.

- Ensure that fuel pressure is sane. 40psi with no vacuum reference is generally about where most OEM regulators are set. You should be able to see a difference in fuel pressure between key-on-engine-off, idle and blipping the throttle. Fuel pressure should be lowest when vacuum is highest. Fuel pressure should increase when you blip the throttle as manifold pressure increases.

- You need a MAF capable of metering enough air for your power goals. There are ways to increase the metering capacity of a given meter, but tuning that properly is an advanced topic. Keeping it simple: get a meter that can handle your airflow needs.

- You need a functioning alternator and battery. Battery voltage plays a role in crucial things like injector opening time and coil charge duration. If your charging system is not functioning correctly, your tune may drastically change if/when you fix it. Rule of thumb: if your battery voltage ever drops below 13 volts with the motor running, you will run into trouble.

- On a similar note, underdrive and overdrive pulleys can cause real issues. Pay attention if you see them.

- Check for emissions hardware ( purge, smog pump, EGR, etc. ) that is missing. In many cases these items can be disabled but you need to pay attention to what is present compared to what the ECM expects.

- Basic maintenance should not be overlooked. If it is important for a “normal” car it is twice as important in a performance application.

- Spark plugs: correct heat range, appropriate gap, not fouled. Consider power level, fuel and ignition system. AVOID PLATINUM PLUGS FOR PERFORMANCE APPLICATIONS!!! Copper or iridium will serve you much better.

- Plug wires: no cracks/arcing, properly crimped ends, appropriate length so there isn’t too much tension

- Firing order: firing order is determined by the camshaft (mostly) not the block or computer.

- Spark boxes: great for distributor engines, unneeded/problematic for mod motors

- Coil packs: Coil-per-cylinder (99-04 generally) applications like ***OEM*** coils best. (according to Dave B.) MSD, Accel, Granatelli, … are all cause for concern especially with boost.

- Oil and coolant: always check fluids before starting. Quick check, potentially horrible consequences if low/out.

- Fans / overheating: it is always a good idea to check that radiator fans work. A car that overheats cannot be tuned.

- Belts and Idlers: All serpentine belts must be in good shape. Cracks, missing ribs, etc. will all cause problems. Any idler pulleys must spin freely.

- Tension: Belt Tensioner should not be extended fully with the engine off. Adjust belt length so that tensioner is in the lower third of its adjustment range with the motor off. (i.e. it can move 2/3 through its range to increase belt tension – it should be mostly compressed when motor idle) This is particularly important for supercharged applications.

- Fuel filter: Fords are *horrible* about clogging fuel filters. Especially if the car has been sitting for any significant period of time, change the fuel filter. Motorcraft/OEM filters seem to hold up better than many cheap aftermarket ones.

- Fuel age and type: Gasoline degrades with time. Do not expect fuel that is more than a month or two old to be of the same quality as fresh gas. Be particularly careful with heavily oxygenated fuels (i.e. VP Q16) and alcohols (ethanol, methanol, E85, etc.) in contact with fuel system components for large periods of time.

- Clean air filter and MAF. Oiled filters generally cause MAFs to get dirty. Clean MAFs only after they have had a long time to cool – hot MAF+liquid=death. Clean *GENTLY* with brake clean, starting fluid, or other organic solvents.

- Remember, you can’t fix mechanical or electrical issues by reprogramming the ECM!!! The results you achieve with tuning will only be as good as the material you start working with. Garbage in, garbage out.

Datalogging: What’s important and what does it mean? What should we be interested in? What to select?

- There are certain sensors that you will almost always want to keep an eye on because they are critical to engine operation:

- RPM – how fast the motor is spinning

- MAFV / MAF counts – a “raw” value representing the reading from the MAF sensor

- Airflow – a value calculated by the ECM from the raw sensor MAF voltage that represents how much air is being ingested by the engine. This is often represented in some form of “real world” value, like Kg/hr or Lbs/min

- Load – from 94-2004 “Load” is the main factor involved in determining spark advance.

- Spark Advance – when the ECM is commanding sparks to be fired.

- TPS – Throttle Position Sensor. How far open the throttle is, i.e. how hard you’re pressing the gas pedal

- ECT – Engine Coolant Temperature(how hot or cold coolant flowing through the engine is)

- IAT – Intake Air Temperature (how hot or cold air entering the engine is)

- Depending on what you are trying to do, there are other items you may want to pay attention to as well.

- Injector Pulsewidth – How long the injectors open. This can be useful both for “sanity checking” and to ensure you do not run out of injector – there is only a fixed time available at a given RPM to fire injectors.

- HEGO1/2 – Heated Exhaust Gas Oxygen sensor. Measures the presence or absence of oxygen in the exhaust in order to try to determine whether the motor is running rich or lean. Watching the raw HEGO voltages can give you some kind of very basic indication of fueling. These sensors experience a large change in voltage in a very small area centered around a stoichiometric mixture ( 1.0 lambda or about 14.7:1 Air-Fuel Ratio or AFR)

- STFTs – Short Term Fuel Trims. These are IMMEDIATE changes the ECM makes in response to HEGO readings in order to steer the air-fuel mixture towards desired targets. If your EEC uses STFTs effectively (i.e. all modular motors) then these are generally more effective as a tuning tool than looking at raw O2 voltages.

- LTFTs – Long Term Fuel Trims. These are the long term difference between programmed values and target values. Think of them as the average of STFTs over a long time. If your EEC uses LTFTs effectively (i.e. all modular motors) then these are one of the most effective pieces of data provided by the stock computer for tuning fueling.

- WBO2 – Wideband Oxygen meters can measure a much wider range of rich-lean conditions than standard HEGOs. Having wideband data is often preferable to HEGO/STFT/LTFT. In many cases (i.e. 86-95 in my opinion) it is often easier to disable closed loop operation/the O2 sensors completely and tune the car exclusively using a wideband.

- ISC Integrator (‘integrator’) – this represents the difference between how much air the EEC is using to hold and idle versus how much it is commanded to hold in the tune. Critical for proper tuning of larger camshafts and larger displacement engines.

- Boost/MAP/Pressure – Although MAF systems do not differentiate between boost and vacuum, it is often very handy for sanity and safety to have an idea of how much pressure there is in the intake manifold. For positive displacement blowers (roots, TVS, twin-screw) make sure you take pressure readings AFTER the blower on the lower plenum.

- Pressure drop across injectors / FPDM duty cycle – most 99-04 cars control fuel pressure electronically. These values are critical to a properly operating fuel system on these vehicles.

Recalibration: Modifying Parameters and Values to Achieve a Target

- First step: decide on target operating parameters for the engine

- This may seem obvious, but something as simple as “make the most power” or “improve fuel economy” isn’t going to be be enough.

- Second step: take a general goal like “make the most power” and decide on appropriate engine conditions to achieve that goal.

- If you read these rules of thumb and say “this isn’t right for my engine” – GREAT. You already know more than the audience these rules are aimed at.

- If in doubt, “0.8 is great” – blatant simplicity. Quoted me to once by someone who did OEM calibrations for Honda for a living. It is very difficult to break anything due to fueling from running a vehicle at 0.8 lambda (about 11.6:1 AFR Gasoline)

- 1.0 Lambda represents a stoichiometric mixture – exactly enough oxygen is present in the air to burn all the fuel supplied. This is normally the best mixture for minimizing emissions.

- Most vehicles make best power around 0.85 to 0.88 lambda (12.3 – 12.7 AFR Gasoline) – slightly richer than stoich

- Most vehicles achieve best fuel economy at around 1.05 to 1.1 lambda ( 15.2 to 16.0 AFR gasoline)

- Most vehicles need more ignition advance as RPM increases

- Most vehicles need more ignition advance under cruising/low-throttle conditions than WOT

- Knock is most likely close to peak torque, at high loads/low RPMs or at peak horsepower

- Next step: Get familiar with the strategy your vehicle uses. Fueling, timing, idle, open-closed loop and just about everything else vary considerably from one strategy to another. Being familiar with the strategy your ECM uses will help you figure out which tables to modify to acheive the results you seek.

- eectuning.org is a good place to learn more.

- the ‘Education’ section of moates.net is another good place to get information

- After you figure out where to look: set up what you can based on what you already know

- Setup Engine Displacement / displacement of one cylinder

- Setup injector size

- Setup a reasonable rev limiter based on what you know of bottom end and valvetrain

- Setup a reasonable (perhaps a little high to start) value for target idle

- Setup a reasonable base calibration for MAF sensor. If sensor came with a calibration sheet, this would be great time to use it.

- Setup a reasonable target air fuel while in open loop

- Setup a reasonable timing map. A stock timing map adjusted for mods is always a good place to start.

- Setup a reasonable pattern from switching from closed loop to open loop.

- Enable or disable hardware such as O2 sensors, EGR, Purge/Evap, automatic trans

- If you take your time to create a sane starting point before you turn the key on you will save yourself countless hours of time!

- Finally: Start your engines (and your datalogger) and make final adjustments

- Are air fuels not matching what you command in open loop?

- Three pieces of the fueling puzzle: MAF transfer, Injector slopes(size), Injector offset (battery compensation – latency)

- How do you tell what is going on? STFTs, LTFTs (if O2s are enabled) combined with a wideband. STFTs/LTFTs are great while O2s are active – i.e. part throttle

- Leanest at idle, small pulsewidths but perfect at WOT/higher throttle -> increase battery offset

- Lean – rich – lean patches as you gradually increase throttle -> wrong shape of MAF curve. systematically tune it

- Entire range of engine operation uniformly off from commanded values -> either injector slopes (size) or entire MAF transfer function is off. Let load determine which one to multiply/divide in order to fix things

- Idle issues?

- Make sure your MAF transfer table, injector slopes and injector offset are sane before trying to fine tune idle!

- Follow the integrator – a good place to start is to add the integrator (or subtract if it is negative) from the Neutral Idle Air table (in neutral) or Drive Idle Air table (if in Drive for automatic cars)

- Performance

- ALWAYS TUNE FUELING FIRST BEFORE TACKLING TIMING! You are *much* more likely to break your engine if your mixture is wrong. As long as your timing is good enough to light the mix, you can tune fueling adequately.

- Tuning timing without a dyno is hard. Accelerometers and a dragstrip can provide crude but repeatable feedback.

- Are air fuels not matching what you command in open loop?

Data Analysis and Evaluation

- Once captured, the operational data can be analyzed and used to guide calibration effort.

(More to come!)

(below this line is draft / coming soon as of 2010-11-30)

Chapter 4: Software/Hardware Initial Configuration with Tuning Session Start-Up Examples

- Physical installation of hardware is shown in more detail from Chapter 1 overview.

- F3

- Jaybird

- Quarterhorse

- F8/destiny and switch

- Wideband

- Installation, licensing, initial configuration, and detailed hardware synchronization procedures for each software are explained and examples detailed. Initial basic calibration load-up for different hardware, as well as basic payload creation for datalogging, are explained and illustrated for each.

- USB Driver

- BE/EA

- EEC Editor

- TunerPro RTv5

- Flash & Burn

- F8/Destiny Utility

- Data Analysis and Evaluation

- Once captured, the operational data can be analyzed and used to guide calibration effort.

- Several examples of logged data values and how they relate to calibration parameters are provided.

Chapter 6:

Case Studies: Example Modifications, Vehicle Combinations, and Rules of Thumb

- Key Issues and Vehicle-Specific Examples

- How do many of the popular modifications on these vehicles affect the tuning approach?

i. Bigger MAF

ii. Bigger injectors

iii. Cold plugs

iv. Nitrous

v. Gears and converter

vi. Auto vs Manual

vii. Emissions delete / racing modifications

viii. Cam, heads

ix. Headers/exhaust

x. Cold air intake

-

- We look at a walk-through of important considerations and the thought process of tuning several different example combinations, with real-world dyno results.

i. A9L/GUFB Fox Body, 1993 N/A 331 stroker, 24# injectors, cam, headers, 5spd.

ii. CBAZA, same as above.

iii. 03/04 Mustang

iv. SC A9L

v. SC 03/04 Cobra

vi. F150 Truck

-

- Achieving an Optimized Result: When is it good enough?

i. What are your goals?

ii. Do you plan for future modifications?

iii. Rules of thumb for AFR and timing, NA vs boost.

iv. What is safe vs aggressive?

>

>

>

> Vehicle Compatibility

>

> All year/model Ford 2004 and earlier with J3 port are compatible

***with our hardware*** but there may not be software support for particular models.

> Some vehicle year/model applications are simply not supported in the

> software because of lack of definition information. It’s important to

> evaluate the availability of your desired application as ir relates to

> the software selection process. You may be out of luck (for example,

> 1995 Festiva or such uncommon target).

http://support.moates.net/ford-strategies-supported/

http://support.moates.net/ford-box-code-strategy-cross-reference/

>

>

>

> Overview of Tuning Process

>

> Determine your target vehicle boxcode and strategy

>

> i.

> Boxcode is typically a 4-digit letter/number code on the EEC computer.

> This is the calibration code.

http://support.moates.net/ford-information-we-need-to-help-you/

>

> ii.

> Strategy is the ‘parent’ definition structure to which a boxcode belongs.

Each strategy is the set of procedures that are executed on your ECM to run an engine. Sometimes more than one strategy can successfully run on a given ECM. Normally we do not make many changes to the procedure part of strategies while tuning vehicles. Instead, we change tables, functions and constants so that the engine receives what it needs to run well. Each “box code” represents a configuration of a particular strategy for a particular engine.

>

> iii.

> For

instance, the A9L boxcode belongs to the GUFB strategy. The A3M boxcode also belongs to the GUFB strategy. If you compare A9L.bin and A3M.bin the files will be almost identical because they use the same strategy but are configured for different vehicles by Ford. If you get a definition (also called def) for the GUFB strategy, you will be able to edit both A9L and A3M binaries because they use the same strategy.

……….

> iii.

> J3 port MUST be thoroughly cleaned, both sides, before installation!

***IMPORTANT***

……………….

> Chapter 5:

>

> Suggested Techniques for Effective Calibration of EEC Systems

>

>

>

>

>

> Vehicle Inspection and Preparation

>

> CRITICAL part of the tuning process. Start here, really.

> Several areas of the vehicle should always be analyzed before you

> begin the effort.

>

> i.

> Check base timing, adjust as needed. On older Fords, pull “spout” timing connector either by distributor (86-93) or on passenger fender side (94-95). Adjust distributor to achieve 10 degrees base timing with spout removed. Reinstall spout before tuning.

>

> ii.

> Evaluate TPS voltage, make sure it is in range through motion.

Vehicles are very sensitive to improper TPS voltage. TPS being too low or too high can cause the ECM to not enter the correct idle mode.

TPS should be between 0.95 and 1volt with throttle plate closed. This can be checked using QH quite nicely.

>

> iii.

> Look at MAF intake routing, make sure there are no gross vacuum / intake leaks.

http://support.moates.net/tuning-maf-systems-and-air-leaks/

See how much or little of that you want to put here.

>

> iv.

> O2 sensors should be operational, exhaust should be leak-tight at

> least that far back.

OEM Ford O2 sensors work a million times better than cheap aftermarket ones.

Ideally, a wideband sensor is to be installed in addition to the factory O2s rather than instead of one.

If this is not possible, it is greatly preferable to remove a secondary (Post-catalytic converter) O2 sensor.

If a primary O2 sensor has the be removed in order to install a wideband, make sure closed loop operation is disabled.

>

> v.

> Basic maintenance should not be overlooked.

>

> 1. Plugs and wires

1a. PLUG GAP IS REALLY IMPORTANT

1b. Appropriate plug type is really important (Copper, Silver (Brisk for 3v)). Iridium plugs are ok for applications with extremely strong spark boxes or CDI systems. Avoid platinum plugs like the plague.

>

> 2. Oil and coolant

>

> 3. Fuel filter and fuel age/quality/octane

>

> 4. Clean air filter and MAF

>

> vi.

> Ensure that fuel pressure is as expected through operating range.

>

> Remember, you can’t fix mechanical or electrical issues with reprogramming.

> Tuning is about more than just flipping chips, so make sure your

> vehicle is in good shape!

This really can’t be stressed enough. Tuning a car that isn’t running right is like putting a bandaid over a gangrenous wound! The first step to tuning a car properly is to make sure it is mechanically sound!

>

>

>

************I’m not sure I would get into datalogging just yet because we haven’t talked about recalibration yet.****************

> Datalogging: What’s important and what does it mean? What should we be

> interested in? What to select?

>

> RPM

> MAFV

> Kg/Hr

> Spark

> HEGO1/2

> TPS

> ECT,IAT

> Load

> WBO2

>

***********************************Snip*********************************************************************************************************

>

>

> Recalibration: Modifying Parameters and Values

>

The purpose of recalibrating an ECM is to produce the behavior you desire, and by doing so hopefully improve performance, emissions or other operating characteristics. Normally, there are two stages to this process.

First, parameters within the strategy are altered to match physical parameters of the engine. Engine displacement, injector size are the primary values here. Also, the MAF transfer function should be altered to match the MAF that is installed on the vehicle. You can often “rob” a MAF transfer function from another vehicle’s strategy when using the MAF from another vehicle.

Next, operating parameters are changed in order to achieve the actual running conditions desired for the particular engine. In many cases, simply adjusting the “configuration” items for the strategy in the first step will make then engine run great but there are almost always small changes that can be made to optimize performance.

>

> What are the most common values we will need to modify?

>

i. Displacement – how large the engine is

ii. Injector slopes – define how much fuel flows through

injectors, aka injector size

iii. MAF calibration – defines how much air enters the engine as

a function of MAF voltage. aka MAF transfer function iv. Rev limiters – protect the engine from being damaged by over-revving

v. Speed limiters – protect the driver from his/her own stupidity

vi. EGR delete, PATS delete, secondary O2 delete – turn off items that are not present or not desired.

>

> How do we know which values to change, and by how much?

>

(repeat / correlate with above)

First step: calibration data should match actual equipment specification

example: If you have a 347 stroker with 30# injectors your strategy should be configured to match these physical parameters

Next step: start your engines, identify problems and goals. There are hundreds (if not thousands in some cases) of parameters you can change. Before starting on tuning, it’s good to have an idea of what’s not right, what you’d like to improve and what you can leave alone. This may sound basic, but maintaining some kind of focus is really important to working effectively. Examples of things you might want to work on are improving idle, improving wide open throttle performance, decreasing fuel consumption.

After figuring out what aspects of running the engine you want to work on, it is time to get the data you need to achieve your goals. By selecting appropriate items for datalogging, the QuarterHorse allows you to view, log and replay the same data that your ECM uses to run your engine. Instead of blindly guessing which values you need to change in order to get the engine behavior you seek, you can use this process of logging, analyzing logged data and a little math to make appropriate changes.

Now specific tasks in the tuning process will be examined in detail.

This will be presented as a mixture of theory and practice. The next chapter will serve as a guide for how to adapt the programming of your ECM to suit specific modifications (cold air kits, injectors, motor transplants, etc) and will be attempt to be primarily hands-on.

Routine tuning processes: (these are going to need more explanation, I’m just running out of steam tonight)

Basic setup – Slopes, injectors, MAFs, sane spark tables

WOT / Open loop fueling – MAF transfer, inj slopes, stabilized fuel table

Closed loop fueling – O2 trims, MAF transfer

Power tuning – Dyno, spark tables

Idle tuning – idle RPM drive, neutral, Drive idle air, neutral idle air, integrator, gains, etc

Dashpot – role, tuning, scalars, preposition

>

>

>

> Chapter 6:

>

CASE STUDIES AND HANDS ON PRIMARILY. Theory / processes in previous chapter

>

>

>

>

>

> Key Issues and Vehicle-Specific Examples

*MAKE MORE SPECIFIC* General procedures covered above

>

> How do many of the popular modifications on these vehicles affect the

> tuning approach?

>

> i.

> Bigger MAF

>

> ii.

> Bigger injectors

>

> iii.

> Cold plugs

>

> iv.

> Nitrous

>

> v.

> Gears and converter

>

> vi.

> Auto vs Manual

>

> vii.

> Emissions delete / racing modifications

>

> viii.

> Cam, heads

>

> ix.

> Headers/exhaust

>

> x.

> Cold air intake

>

> We look at a walk-through of important considerations and the thought

> process of tuning several different example combinations, with

> real-world dyno results.

>

> i.

> A9L/GUFB Fox Body, 1993 N/A 331 stroker, 24# injectors, cam, headers, 5spd.

>

> ii.

> CBAZA, same as above.

>

> iii.

> 03/04 Mustang

>

> iv.

> SC A9L

>

> v.

> SC

> 03/04 Cobra

>

> vi.

> F150 Truck

>

> Achieving an Optimized Result: When is it good enough?

>

> i.

> What are your goals?

>

> ii.

> Do you plan for future modifications?

>

> iii.

> Rules of thumb for AFR and timing, NA vs boost.

>

> iv.

> What is safe vs aggressive?

>

>

Establish communications, check settings.