|

|

| Instructions for using the ‘HDR1′ Memory Header

The HDR1 memory adapter is primarily designed to download the existing code from a stock Memcal. Step 1: Take the stock Memcal (or whatever) and identify where the pins come out for the existing EPROM. Step 2: Insert the HDR1 into the Memcal and note the orientation of the existing chip. Step 3: Place the assembly into your favorite chip reader / programmer (AutoProm shown, chip notch facing ZIF handle, empty spaces nearest to handle). Step 4: Go ahead and read or re-program the chip. That’s it! No mess, no fuss. Pretty straightforward. |

HDR1

G3/GP3 Configuration and Use

|

|

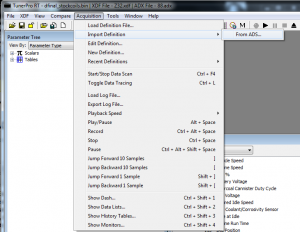

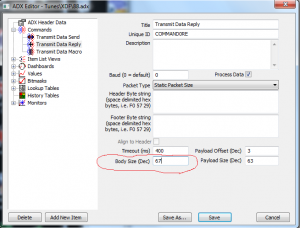

| The ‘G3′ Switching Adapter (also: Using the ‘EX’ with the G3) For placing several different binaries on a single chip for GM applications, the G3 adapter is the hot ticket. By ‘stacking’ the binaries on a large-sized memory, and using the included switching ability, you can swap between different programs on-the-fly while the car is running. You could have ‘Valet’, ‘Economy’, ‘Nitrous’, or whatever else you want to put together. First a little background. A memory chip is accessed by changing the state of various connections or pins. Some of the pins are called address lines. They tell the chip which data to present. There are low address lines (A0 through A14) and high address lines (A15 through A18). The larger chips like the AM29F040 have A0-A18, or 19 address lines. What the G3 adapter does is take ‘manual’ control of the address lines A15-A18. If you study binary stuff, you’ll know that this will give you 16 different memory ‘banks’ which can be selected. On the G3 are several components, including one thermofuse (looks like a capacitor) to protect against shorts when using the ‘EX’ module, four capacitors which help dampen RFI pickup from the EX cable, two jumpers to set the operating modes (see below), and a rotary DIP switch to select which bank of memory is to be accessed. Installation instructions for the G3 adapter are very similar to those for the ‘G1′ adapter, so see the section under ‘G1′ instructions for guidance in this regard. Think of the G3 as an old-style channel selector on a TV. You just turn the knob, and the car’s ECM will see a different channel or ‘bank’ of memory. Put the switch to position zero, and all the ‘high’ address lines will be set to 5v. Thus, the actual memory location that will be accessed on a 29F040 will be 78000-7FFFF. If the switch is set to position ‘F’, then all the high address lines will be set to GND, or ‘low’. In this case, the reference memory will be 00000-07FFF. You can see how this lets you put up to 16 programs on a single chip and select between them. The switch positions are numbered 0-F, which is just hexadecimal for zero through 16. There are several different hardware configurations which are possible with the G3. This increases flexibility along with the confusion factor. Let’s look at these combinations individually: 1) Putting a 29F040 chip in the G3, and operating with an ECM that originally takes a 27C128 (16k bin) or 27C256 (32k bin). This gives you 16 bins. The most typical cases are (1) and (2), so we’ll talk about them first. For operating instructions on the ‘EX’ module, see the bottom of this page. Case 1: First thing you will want to do is ‘assemble’ your big 512k binary from a group of smaller ‘stock-size’ binaries that you create or collect. The screenshot shows the configuration screen in ‘TunerPro’ under the BIN stacker function whereby the proper settings have been selected. Case 2: If you want to use the G3 as just a straight adapter and not a switcher, this can be done very easily. Just program the chip as you normally would for a single-program application and put it in the adapter. Case 3: Now we’re getting to some more ‘flexible’ appication of the G3. For this case, the jumpers should be set as shown, with J1 in the ‘down’ or 29F040 position and J2 (right) in the ‘up’ position. You still stack your BINs using the TunerPro Bin Stacker, but the settings should be such that your Bin Size=64k, Chip Size=512k, and Switch Size=64k. Case 4: OK, so you don’t want to run 16 different binaries? Just two? Here’s an option for you. Set up your BIN in TunerPro again, with the Bin Size=16 or 32k, chip size=64k, and switch size=32k. Set the jumpers with J1 in the ‘up’ position and the J2 in the ‘down’ position. This will allow the A15 line to get switched every other switch position. That’s about it in terms of G3 operation. Again, the installation is pretty much the same as for the G1 so see that section for instructions in that regard. Using the ‘EX’ module: The function of the ‘EX’ module is that of a remote BIN switching device and display indicator. When used with the G3, the ‘local’ G3 rotary switch should be placed in the ’0′ zero position!

That’s all there is to it! |

Honda Tuning with Crome Tutorial

|

|

| This is a very nice PDF tutorial written up by Darren Kattan. Check it out by clicking HERE. |

HULOG/HondaLog Installation

|

|

| Installation of Honda-Based USB Datalogging Tools

There are two tools available for datalogging on Honda ECUs from www.moates.net and they include the HULOG and the HondaLog. HULOG: The HULOG comes in a plastic enclosure and ONLY requires a pin swap if it is an older unit. All the new units come with 1:1 connector pinning, so will differ from the pictures shown in that no pin swap is required or will be present on the extension cable. It can be mounted externally or internally, depending on whether you want to pass the 4-pin header cable or a USB cable out of your ECU. HondaLog: The HondaLog can be mounted directly to the ECU with no interconnecting cable It can also be mounted at the end of a 4-pin tether cable. Either way, no pin swap is required (note color of wires and their order in the pictures). The unit is shipped with two pinning options in terms of the attachment header. It also comes with a piece of shrink-wrap tubing in case you want to ‘wrap that rascal’ when you’re done. Either way, it goes to your USB cable and PC on the other end. Pictures are shown below for the two units. The installation header is a 4-pin latching unit, and comes with the moates.net Honda Chipping Kits. You can alternatively use a 4-pin 0.025″ square-post breakaway header. Please take note of the directionality of the latch on the interconnecting cable though, since that is critical. HULOG Pictures HondaLog Pictures |

Bluetooth Install on Ostrich

|

|

|

For the Ostrich2, the following will show you how to install the Bluetooth into the unit:

1) Open the Ostrich (two screws), keep track of the two nylon spacers.

2) Gather up the Bluetooth kit parts as shown in the pictures below.

3) Place the pin headers on the Bluetooth module and snap them on, and then solder it in place as shown.

4) Screw the unit back together (no cleaning necessary) and connect using Bluetooth software (separate tutorial available).

For the original Ostrich, look here:

Ostrich BT Install Pictures

Basically, it is as follows: 1. Remove jumper caps and install shielded angle header. 2. Install module. 3. If you want to go back to USB, then REMOVE bluetooth module and you can put the jumper caps back in place. |

Honda Chipping Kit Install

This is Keebler65′s old guide. Some of the chipset and software info is a bit dated, but the techniques are good.

ECU Chipping

You need to add a few additional components to the original Honda ECU. It requires some soldering skills and should not be attempted unless you have soldered before. (Chances are you know someone with soldering skills that could help you). Here is a picture of the P28 ECU that I chipped, before any of the parts were put in:

Before you can solder the parts in, you will need to de-solder the holes in the circuit board since they come filled with solder from the factory. You can buy a “solder sucker” to do the job, however unless you get a nice one (expensive) they don’t really work well in my opinion. The cheap and easy solution is to buy some solder braid. It’s just braided copper. Simply place it over the hole to be de-soldered, and place the soldering iron on top of the braid. It will then wick up the solder into the braid. It’s available at radioshack:

You’ll want to use a decent quality soldering iron to get the job done nicely. The important thing is to not use too much heat, and also make sure the iron has a fine tip on it. I’m using a standard Weller iron:

Here is what it should look like after the board has been de-soldered:

The parts that need to be added are boxed in with a dashed white line. The parts consist of (2) .1uF ceramic capacitors, (1) 1k resistor, (1) wire jumper (simply a piece of wire…I used a lead of the resistor), (1) 74HC373 chip, and (1) 29C256 chip (thats the EPROM). The resistor and capacitors have no polarity, so you don’t have to worry about installing them backwards. The 74HC373 chip does have a polarity. Pin 1 will be on the left side of the pic (you’ll see in detail later one). The same is true for the EPROM chip. Since it would be impossible to burn a chip and have the tune be perfect, it becomes obvious that you don’t want to solder the chip in. Instead, use a socket so that it can be removed. You have two options: for less than $1, you can get a standard DIP socket. The problem is these are very hard to insert and remove the chips since there are 28 pins (it requires a lot of force and is hard to grip the chip). Your second option would be a ZIF (Zero Insertion Force) socket, which costs less than $10. It is a socket that has a lever: pull up the lever, set the chip in/lift it out, and flip the lever back – VERY nice to have since you’ll be doing this many times while tuning. Be careful when ordering the ZIF socket, as many of them are too large to fit on the board without running into things. The first ZIF I bought was made by Aries, and it was a very quality piece, however, it was too large and bulky to fit without a lot of modification to other components on the board. I ended up ordering a different one that was much more compact. I am unaware of the brand, however it is blue and is referred to as a low-profile ZIF. The only problem was that the lever end of it was in the way of the 74HC373. The easy solution is to buy a standard DIP socket as mentioned above. Solder this onto the board. Then, stack the ZIF onto this socket, which raises the ZIF away from the board enough to clear the surrounding parts. This setup worked very well for me. The following picture shows the too-big-to-fit ZIF in the back-left, the low-profile ZIF in the front left, and the DIP socket on the right:

The ZIF socket stacked on the DIP socket for added height:

And finally, a couple of pics with all of the parts installed:

I ordered most of my parts from www.jdr.com except for the low-profile ZIF socket and DIP socket, which I obtained from www.jameco.com. The following table containse the exact part numbers that I ordered. You’ll notice that I ordered two EPROMS. This way, it will be easier to burn one while the other is installed.

| Part Number | Quantity | Description | Source |

| 29C256-12PC | 2 | This is the chip that you burn with Uberdata | JDR |

| 74HC373 | 1 | The other chip that is reqired | JDR |

| R1.0K | 1 | 1K resistor | JDR |

| .1UF | 2 | .1uF capacitors | JDR |

| 102744 | 1 | Low profile ZIF Socket | Jameco |

| 40336 | 1 | 28 Pin DIP socket | Jameco |

Additionally, I have recently located all of the parts you will need from one source. DigiKey is where you can find them. Their inventory selection can be overwhelming, so here are the part numbers you will want:

| Part Number | Quantity | Description |

| AT29C256-70PC-ND | 2 | This is the chip that you burn with Uberdata |

| MM74HC373N-ND | 1 | The other chip that is reqired |

| 1.0KEBK-ND | 1 | 1K resistor |

| 478-4279-3-ND | 2 | .1uF capacitors |

| A347-ND | 1 | Low profile ZIF Socket |

| A409AE-ND | 1 | 28 Pin DIP socket |

And for a final update to this page, I’d like to add that you can find ALL of the necessary chipping parts at moates.net. It is a great deal in my opinion, and you’re guaranteed to get the correct parts the first time around. It’s under the name of “Honda ECU Chipping Kit”.

Ostrich 1 Operation

|

|

| Here’s how you install the Ostrich: (Much of this will apply to the Ostrich 2 as well but pictures will be different.) 1) Get on the website here in the ‘software and drivers’ section and download and unzip the ‘USB Drivers’ file. Remember where you put it. 2) Plug the Ostrich into the USB port of your PC, and point the operating system to the previously located USB Driver directory and install the drivers. See the USB Driver Installation Guides here on www.moates.net for further guidance in this regard. 3) Go into the drivers and set the COM port of the USB to Serial Converter (under Ports in the Device Manager of the Windows Control Panel). Set it to COM3 or COM4. Override any warnings against ‘port in use’ or any of that nonsense. Again, refer to the USB install guides for more info. 4) While in the port settings, set the latency to ’1′ (default=16). This will speed it up dramatically. 5) Use TunerPro RT or a similar program to upload a binary to the Ostrich, and verify that it is uploaded correctly. 6) Hook it up to the vehicle, and go to town. When installing the ribbon cable where the chip normally goes, orient the red stripe so that it faces where the chip notch or arrow (pin #1) would normally face. Note: If you have the car off, and the Ostrich is hooked up to the car’s ECU, then sometimes an upload/verify won’t work right. Just turn the car on, or disconnect the Ostrich during the initial upload, and everything should be fine. There are jumpers inside the Ostrich, depending on how many pins / memory size you are emulating to. 24-pin (with associated pictures for an installation where the original chip was a 2732A in a 1227747-style GM ECM):

28-pin Installation using the G1 chip adapter, similar to that used in a 1986-92 TPI GM ECM: 32-pin Jumper Settings, presently only used for EEC-V applications: |

|

O-Meter

|

|

| The O-Meter’s physical dimensions are 2.500″ x 1.625″ x 0.800″Check out the documentation to understand what all this unit can do! Does AFR/Lambda/Universal display, data storage, etc. Fully user configurable through two easy-touch buttons. Available in red (brighter) or blue (not as bright but looks cool!). Blue is a little more because of the parts cost.

Here is the instruction guide for the O-Meter so you can read about all the features: Here is a video of the O-Meter in action: Here are pictures of how to hook up the wiring between the O-meter and the LC-1: |

Demon

Introduction

Software Support

As of 11/03/09 software support is as follows:

Neptune: Full emulation+data+onboard (release)

ecTune: Emulation+data (release)

Crome: Emulation+data (beta)

Please note that each Demon has a serial number – NepTune and eCtune both license a single copy of the software to a single Demon. The exact procedure for this is different for each software package.

Datalogging Memory

The first production runs of Demons have 1 Mbyte memory for storing datalogging. Current (starting around April 2010) production units have 4Mbyte memory. Early production units can have their memory upgraded. If you are interested in this service, purchase the Install Service item and note in the “Comments” field of your order that you would like the Demon memory upgrade. You’ll have to send your Demon back to us – turnaround time is normally about 2 weeks.

Switching Between Software

You can now more easily switch among the different applications using our Config Utility for resetting the state of your Demon.

Indicator Lights

The Demon has two LEDs to indicate its status, one red and one green.

The red LED serves as a hardware status indicator and/or busy light. It can come on when:

- Demon is currently processing a command (upload/download/etc)

- Poor / nonexistent connection between Demon and ECU 28 pin socket. (usual cause: faulty installation)

- Poor / nonexistent connection between Demon and ECU CN2 port. (usual cause: cabling, cable backwards, faulty installation)

- Demon is powered via USB but there is no power to ECU

- NEPTUNE RTP ONLY: No serial communication between ECU and Demon

- Red LED will blink when onboard packets are being stored to memory

The green LED is more of a data packet and status indicator light. It typically behaves as follows:

- Lights up solid green when the Demon is powered on

- Blinks when the Demon is communicating with the ECU (assuming data packets are configured correctly)

- Fast blinking means data is flowing properly from ECU to Demon via CN2

- Slow blinking likely means data timeout / incorrect connection/configuration

EmUtility: standalone emulator control

Introduction

Ever wish your favorite Moates emulator would work with your favorite ROM editor software that doesn’t have native support for our products? EmUtility (from the author of TunerPro) allows you to use Moates emulators with any software that can spit out a binary (bin) or hexadecimal (hex) format file. It supports the Ostrich1, Ostrich2, APU1 *and* RoadRunner! It can even support more than one emulator connected to the same computer simultaneously. (this requires more than one instance of the program, one for each emu)

Installation

You can get EmUtility from the Utilities section of TunerPro.net

EmUtility may require additional files to be installed for it to work, specifically the Microsoft Visual C redistributable libraries, which are also linked off the Utilities section of TunerPro.net

EmUtility does not come with an installer – it is shipped as a zip file with a single program file inside. Unzip it to place where you will be able to easily find it, such as your desktop. You can run it directly from the desktop and it will not make a “mess” because it is only one file.

Usage

EmUtility is pretty straightforward to use.

First, start the program. You should see “Detecting Hardware… Ostrich 2.0 blah blah blah” for instance. If you see “No Hardware Detected” check your cables and connections. If you cannot get your hardware to detect, try looking at our USB Troubleshooting Guide.

After you have verified that your hardware has been detected properly, click the “…” next to “Input / Output File” to select a file to use. (If you are going to read the contents of the emulator to a file, this can be a new file)

Next select an operation from the drop down box next to “Operation” Valid operations include:

- Read from emulator to file = creates a new file on your computer with the contents of emulator RAM. Must specify a filename, how much memory you want read (size), if you want to use a non-standard start address (File Start Address) and if you want to use large RAM support (required for files > 512kbit / 64k byte)

- Write from file to emulator = updates the RAM on your emulator with the contents of a file on your computer. Must specify a filename and if you want to use large RAM support (required for files > 512kbit / 64k byte). File size and start address will be automatically selected for you and will be correct in most cases where your file is the same size as the chip you are trying to emulate. (i.e. 32k byte file for 27C256 chip)

- Verify emulator RAM with file = compares the contents of the Emulator’s RAM with a file on your computer to see if they match. Must specify a filename and if you want to use large RAM support (required for files > 512kbit / 64k byte). File size and start address will be automatically selected for you and will be correct in most cases where your file is the same size as the chip you are trying to emulate. (i.e. 32k byte file for 27C256 chip)

- Monitor File for changes and upload = this operation monitors a file for changes and uploads the changes to your emulator as they happen. ust specify a filename and if you want to use large RAM support (required for files > 512kbit / 64k byte). File size and start address will be automatically selected for you and will be correct in most cases where your file is the same size as the chip you are trying to emulate. (i.e. 32k byte file for 27C256 chip)

After you have selected and configued the operation you desire, click “Execute” to perform it. To cancel a monitoring+upload session or other op, click “Cancel Op”

That’s it!

Suggested Uses

If you have a program that can spit out bin files but it does not support Moates hardware:

- Start EmUtility

- Pick “Write from file to Emulator”

- Point EmUtility at the file you are working with

- Click “Execute” to load the initial file

- Change the operation to “Monitor file for changes and upload”

- Click “Execute” to begin monitoring the file for changes

- Leave EmUtility running in the background. Go back to your editing application. Make changes and save the file (with the same filename). As you save changes to the file, EmUtility will copy them to your emulator almost instantly!

Nissan 16 bit applications with TunerPro 4.x: (using a daughterboard like our Nissan 20×2 that takes two identical chips and two Ostrich 2.0 emulators)

- Plug in ONE Ostrich and follow the directions immediately above to set up monitoring for an application that does not support Moates hardware.

- Leave EmUtility running and connect the second Ostrich.

- Start TunerPro. It should detect your second Ostrich.

- Start your emulation session in TunerPro.

- Tune away. TunerPro will update one Ostrich, EmUtility will update the other

(Note: TunerPro 5.x supports dual Ostrich mode which is easier to set up than this)

16 bit Nissan applications such as 925style.com’s ROM EDITOR (using a daughterboard like our Nissan 20×2 that takes two identical chips and two Ostrich 2.0 emulators)

- Plug in ONE Ostrich and follow the first set of directions above to set up monitoring for an application that does not support Moates hardware.

- Leave EmUtility running and connect the second Ostrich.

- Start a SECOND COPY of EmUtility. It should detect your second Ostrich.

- Repeat the instructions for loading a binary and starting monitoring in the second EmUtility session

- Tune away! As you save changes to the file, each instance of EmUtility will update one emulator.

Using the RoadRunner as a general purpose 16 bit emulator with software that does not have native support (i.e. Bosch Motronic 28Fxxx):

- Start EmUtility

- Pick “Write from file to Emulator”

- Point EmUtility at the file you are working with

- Click “Execute” to load the initial file

- Change the operation to “Monitor file for changes and upload”

- Click “Execute” to begin monitoring the file for changes

- Leave EmUtility running in the background. Go back to your editing application. Make changes and save the file (with the same filename). As you save changes to the file, EmUtility will copy them to your emulator almost instantly!

Who uses our gear?

This page is being created so we have a place to keep track of all the people who are using our gear for various applications. If you would like to be added or removed from here, please email support@moates.net or leave a comment. Hit control-F to find keywords on this page as eventually we hope this grows to a very large list!

ECU Connections forum – mostly Bosch Motronic stuff.

DS-MAP – MAP sensor conversion for DSM ECUs, supports Ostrich

TunerPro RT – general purpose ROM editor that supports APU1, Ostrich, ALDU1 and most of our gear. Useful for Nissan, Ford, GM, DSM, some Bosch Motronic (BMW, Porsche, VW, etc.) among others. (we sell this)

ThirdGen.org – forum dedicated to the 3rd gen camaro/firebird with a great Tuning section!

EFI Live – Supports our RoadRunner Emulator for OBD2 GM vehicles (we sell this)

Binary Editor – Supports our QuarterHorse emulator for 86-04 Ford vehicles (we sell this)

EEC Editor – Supports our QuarterHorse emulator for 86-04 Ford vehicles (we sell this)

TunerCat – supports APU1, ALDU1, Ostrich, etc. for OBD1 GM vehicles

Neptune – supports Demon, Ostrich, BURN2, etc. The premiere solution for tuning 92-01 distributor Hondas (we sell this)

eCtune – supports Demon, Ostrich, BURN2, Hondalog, etc. Another great 92-01 distributor Honda solution

Crome – supports Demon, Ostrich, BURN2, Hondalog, etc. an older and poorly maintained 92-01 distributor Honda solution

TurboEdit – supports Ostrich, Hondalog. an old and finicky software package for 88-91 distributed Hondas

BRE – supports Ostrich, Hondalog. an old and finicky software package primarily aimed at 89-91 Vtec hondas

Pgmfi.ORG – Home of the DIY Honda community. Birthplace of CROME, TurboEdit, BRE and loosely affiliated with other softwares. Still a great resource for Honda ECU tuning.

Nistune – supports Ostrich, dual Ostrich. Nissan ROM tuning software, dealer version works with our hardware. Programs made with Nistune work with our Nissan 2Chip adapter.

Tuning Porsche 944 turbo vehicles using TunerPro, Ostrich, SocketBooster (thanks Joshua)

Turbo Mopars using Ostrich2

RhinoTuning using Ostrich2 / BURN2/ etc. for tuning Suzuki Swift pre-OBD2 vehicles

Nissan Data Voice uses the Ostrich2 for realtime tuning for OBD1 Nissan vehicles

Ford: Box code – strategy – vehicle cross reference

This page is intended to help people who have looked here to figure out if there is support for their vehicle.

Each ECM has a 3 or 4 digit processor code that uniquely identifies it. You can tell what strategy a ECM uses from its box code or from looking at a dump of a stock program from that ECM. “Strategy” is Ford’s lingo for a program to run a vehicle. (or operating system) Each strategy can have multiple calibrations for different engines. Sometimes even V6 and V8 engines will use the same strategy!

If you are wondering if your strategy is supported, take a look at the Supported Strategies guide.

This list will grow over time. If you don’t see your vehicle listed here, email support@moates.net

A9L = GUFB (88-93 “Fox body” V8 mustang 5-speed)

A9P = GUF1 (88-93 “Fox body” V8 mustang auto)

T4M0 = CBAZA (94-95 SN95mustang 5.0 V8)

LLX4 = CDAN4 (96-97 Cobra 4.6L 32v)

PTP2 = FBFG2 (04 Mustang GT)

RCX5 = CDAN4 (97 Tbird 3.8L v6)

SLL4 = CTBAE (96 5.0 explorer ??? )

LKT3 = ODAJ0 (02 F150 4×4 auto)

SCI1 = ODAG0 (02 F150 4×4 manual)

NMI1= ODAG0 (02 F150 4×4 manual)

MIJ1 = ODAG0 (02 F150 4×4 manual)

KVF1 = ODAL1 (02 F150 4×4 manual)

CXN1 = MNAE1 (01 Lightning)

CUX1 = MRAD2 (01/02 Lightning)

CUX2 = MRAD3 (01/02 Lightning)

URB1 = TAUF0 (02/03 Lightning)

There is a handy Excel spreadsheet you may want to look at ( link ) that has a decent cross-reference.

Ford: Strategies supported

Introduction

Although you can use our Ford hardware ( F3 Jaybird QuarterHorse ) on just about any 86-2004 Ford, software is much more lacking. Currently (Feb 15 2011) there are three software packages that support our Ford hardware – Binary Editor, EEC Editor, TunerPro RT. Each software package has a different set of computers that it works with although there is quite a bit of overlap on more popular strategies. For the most part, US and Australian ECMs are best supported – European models are quite lacking in comparison.

Note that most of the information about software support will deal with STRATEGIES not processor codes. We have a box code-strategy cross reference. If you don’t see your box code listed there, we will generally be able to help you figure out which strategy your ECM uses most of the time from its box code – send an email to support@moates.net. Worst case, you will have to read the stock computer (with QuarterHorse or F2E ) and email us the binary.

The following information is REASONABLY up to date as of Feb 15, 2011. (I will try to update it periodically)

EEC Editor – Supported Strategies

The best way to find out what strategies are supported by EEC Editor is to download and install it! After you have updated the software, you can see all supported strategies by looking in the directory “C:Program FilesEEC Editordefinitions” which contains a file for each strategy EEC Editor can open and edit. You can see which strategies support datalogging with the QuarterHorse by looking at the directory “C:Program FilesEEC Editordlms” Please download the software and play with your computer’s definition / DLM prior to purchase as not all strategies are equally complete.

There is also an excel spreadsheet which may be very helpful for determining if there is support for your vehicle. This spreadsheet has more accurate information than this web page.

Supported Editing strategies:

1990F250.DEF

1DDB.DEF

1deb.def

1dec.DEF

1dga.def

2dbd.def

2dca.DEF

2dda.DEF

3dea.def

a9u2.def

AGANF.def

AKAM9.def

akama.def

AKAMH.def

akc0.DEF

AOAG3.def

ATAN0.def

bnaf9.DEF

boae4.def

c3p2.def

C3W1.DEF

cbaz0.def

cbaza.def

CCAQA.def

CCAQE.def

CDAN4.def

CDAN6.def

CDAP3.def

cdba4.def

cfak7.DEF

cmai3.def

cmai7.def

cmai9.def

cmba0.def

CNAB0.def

CNAB1.def

cqab1.def

crai8.def

CRAIA.def

CRAIB.def

CRAIC.def

craj0.DEF

ctbae.def

cvae6.DEF

cvae7.DEF

CVAF1.def

cvba0.DEF

cvba2.DEF

d9s.DEF

DA1.def

GVAKA.def

gvakb.def

gufa.def

gufb.def

gufc.DEF

gure.def

hug02.DEF

HWAD3.DEF

icy1.def

kmak6.def

kqad2.DEF

kraf5.def

LA3.def

LB3.DEF

m2y.def

maag4.DEF

MMAH0.def

MPAM1.def

mrad2.DEF

mrad3.DEF

odal1.DEF

ODAL1.def

OMAD3.def

OMAD4.def

OMAE1.def

OMAE2.def

p2y0.def

PCAG2.def

PCAG6.def

pf3.def

pybd3.DEF

pycl5.def

PYCL7.def

QAAC5.def

qbaa0.DEF

rbadb.def

rbaed.DEF

REAC3.def

reac4.DEF

RGAF2.def

rhagb.def

RQAD6.def

rtai0.DEF

rtai1.def

rtaj0.DEF

RVAF1.def

RVAF3.DEF

rvafa.DEF

rvafb.DEF

rvai1.DEF

RWAI2.def

ryae0.def

RYAF0.def

RYAF1.def

ryak1.DEF

RYBE2.def

RZAN0.def

RZAO1.def

rzao2.def

RZASA.def

rzaso.def

tauf0.DEF

VET1.DEF

way1.def

X2S2.def

Supported Datalogging Strategies:

1DEB_datalog.dlm

cbaza_datalog.dlm

da1_datalog.dlm

fun1_datalog.dlm

gufa_datalog.dlm

gufb_datalog.dlm

gufb_datalog_injector_track.dlm

gufb_dave.dlm

gufb_dave1.dlm

gufb_dave2.dlm

gufc_datalog.dlm

gure.dlm

krdc3_datalog.dlm

p2y0_datalog.dlm

ryaf1_datalog.dlm

(note: this list of DLMs has not been updated as recently as defs)

Binary Editor Supported Strategies

The best way to find out if your strategy is supported in Binary Editor is to download the software and install it! Let it update itself. It should download the latest and greatest strategies available. You can also take a look at the strategies download page at EECAnalyzer.net for more information. Strategies are stored in “C:Program FilesBinary EditorDEF” in a unique folder for each definition.

Please note: datalogging and editing are controlled by the same definition file in BE. You will have to load the definition along with a tune file to get an accurate idea of what exactly is supported.

Please also note: some definitions (that end in “.xls”) can be used by anyone with the software. Other strategy files (those with the “.cry” extension) require additional registration with their author to use them. Derek Fenwick is a particularly excellent strategy author to look for.

Supported Strategies:

(This list last updated 2/15/11 – check http://www.eecaalyzer.net for an updated list)

AHACA (free)

AHACB (pay)

ANY1 (pay)

C1A1 (pay)

CAW0 (pay)

CBAZ0 (pay)

CBAZA (free AND pay)

CCAQA (pay)

CCAQE (pay)

CDAN4 (pay)

CDAN6 (pay)

CZAJL (pay)

CZAW0 (pay)

D1L1 (pay)

D4U1 (pay)

GSALC (pay)

GSALI (pay)

GUF1 (free)

GUFA (free)

GUFB (free)

GURE (free)

LA (free)

LA3 (free)

LB2 (free)

LHBL0 (pay)

LHBL1 (pay)

LHBL2 (pay)

LUX0 (free)

NVMG85 (pay)

PCAF5 (free)

PE (free)

Pops Racing Strategies:

Pops racing and Adam Marrer have started offering definitions for some of the popular EECIV and EECV strategies which are not publicly available otherwise. You can purchase them through Moates.net. Almost all of the 1996-2004 Mustang GT, Cobra, and Lightning strategies are covered here. As of the time of writing (2/15/11) these strategies are offered:

AGANN

AGANF

AHACA

C3P3/C3P2/ICY1

CBAZA

CDAN3

CDAN4

CRAI8

CRAJ0

CVAE6

CVAE7

CVAF1

CVBA0

CZAJL

FBFG2

FBGI0

MRAD2

MRAD3

OMAD3

OMAD4

OMAE1

RTAJ0

RVAF1

RVAFA

RVAFB

RYAF0

RYAF1

RYAK1

RYBE2

TAUF0

TunerPro / TunerPro RT Supported Strategies

One way to find out if your strategy is supported by TunerPro / TunerPro RT is to look at the list of supported definitions. TunerPro supports the QuarterHorse as of version 5.0 which has been released as of the time of writing (February 2011) but QH and strategy support lags considerably behind EEC Editor and Binary Editor. There is extremely solid support for GUFB (A9L / Fox body) and CBAZA (T4M0 / J4J1 / 94-95 Mustang). You can download the TPRT5 specific files here.

Australian EEC Support list

Tuner Pro seems to be the weapon of choice for most Australian EECs. You can get more info and an updated list of supported cars, box codes and strategies here:

Australian EECs : http://www.tiperformance.com.au/technical.html

Tuning: MAF systems, air leaks and reversion

Introduction

As stated in our overview of MAF systems, one of their main weaknesses are air leaks. Whenever air can enter the engine without going through the MAF, weird things happen.

There are two principal kinds of leaks that wreak havoc on MAF systems – constant leaks (like a unplugged vacuum port) and mechanically induced leaks (such as a Blow Off Valve or Bypass Valve that vents to atmosphere.) Each leak has a tendency to affect the system differently. In this article, we will try to take a look at what “should” be happening, what changes with a leak and what kind of odd things you can look for while tuning to identify a leak.

Reversion presents an additional problem for MAF systems. Reversion is the technical name for when air changes direction and reverses flow. MAFs are not one way systems – they will measure air flowing into the engine and then meter the same air flowing out of the engine when there is severe reversion, causing unreliable MAF readings.

Constant leaks

This kind of constant leak in a MAF system is the classic “vacuum leak” where a gasket, coupler or piece of tubing in between the MAF and the engine does not seal properly. In this case, air can enter the engine without passing through the MAF. Because air has entered the engine without passing through the MAF sensor, the MAF sensor reads artificially low. An engine operating in open-loop mode will tend to run very lean. A motor operating in closed loop will see very large positive trims as the computer uses the O2 sensors to add fuel to compensate for the lean condition.

The air leak provides more air for the engine at idle which will make the idle rise or sometimes “hunt” or bounce around unstably. Generally, the idle system will also try to compensate. On Fords you will see the ISC Integrator (“Integrator”) swing negative, indicating the ECM is allowing less flow through the idle valve than is commanded in the tune. It is very common for the Integrator to get stuck at the minimum allowed value and have the car still idle higher than commanded.

Most MAF systems use the MAF for calculating appropriate timing values as well as fueling. With a vacuum leak throwing off the system, the ECU thinks there is less air entering the engine than their really is. This will mean that “load” values will be artificially low, which generally leads to timing being artificially high. In severe situations, this combination of issues (less fuel, more timing) is a recipe for melting engine components if it goes unchecked.

Mechanically induced leaks

Bypass valves are the most common source of mechanically induced leaks although idle, purge and other vacuum operated solenoids can all be a problem. MAF systems require these valves to be re-circulated so that air leaving the valve re-enters the intake AFTER the MAF so it does not get measured twice.

Blow off valves on turbocharged vehicles are often vented to atmosphere. This unfortunately will severely confuse a MAF system. When the valve opens, air that has already passed through the MAF and been “counted” is released into the atmosphere instead of entering the engine. The ECU will supply enough fuel for all the air that has passed through the MAF while only a small portion of this air actually entered the engine. This causes the engine to run very rich and can cause stalling or other problems when letting off the gas and the BOV opens. Once the valve closes again and the car burns off the excess fuel delivered, things slowly return to normal operation.

Supercharger bypass valves can present the same kind of issues when they are allowed to vent to atmosphere. (or when there is a leak in the piping allowing air to recirculate.) Failing to catch an air leak with a supercharger bypass will result in the MAF curve having a sudden change when the valve closes. This will require complete re-tuning of the MAF transfer function once fixed so it is best to catch it early.

Reversion

Reversion is most common in engines with very large camshafts operating at low speeds such as close to idle. Situations where MAFs read unreliably due to reversion can generally be greatly improved by moving the MAF further from the throttle body. Increasing the volume of the intake between the MAF and the throttle body is also effective at smoothing out the pulses of air coming from an engine with a radical camshaft. It is normally possible to get a reliable enough MAF signal in most circumstances. Even extremely wild cams that draw 3-4″ of vacuum at idle can be tamed with an appropriately designed intake system.

Another form of reversion that is troublesome to MAF systems happens with poorly designed supercharger bypass valve systems. In most of these systems, the pipe connecting the outlet of the bypass valve connects with the inlet of the supercharger at an angle where recirculated air flows backwards through the intake. This causes any reverse-flowing air to be metered multiple times by the MAF, leading to unreliable operation. This can almost always be remedied by adjusting the angle of the pipe from the bypass so it points at the inlet of the supercharger directing the flow of recirculated air away from the MAF.

Reversion is very obvious if you are logging the MAF signal. Looking at a graph of a “normal” MAF signal versus time, it will look like a line that could have been drawn without reversing the direction of travel. The same graph of a MAF impacted by reversion will look very “shaky” and jagged, changing direction many times in a short period of time.

Ford Tuning: Load with failed MAF table(s)

Introduction / Prerequisites

Before you read this, make sure you have read Theory: Alpha-N, Theory: Mass Air Flow and the FordOverview. Although not essential, it wouldn’t hurt to have at least read about Speed-Density operation as well. This page will assume you have read and understood these pages. This is a somewhat complicated topic and will require you to put several pieces together so don’t feel bad if you have to read this a couple times.

About the table and why it is critical

The “Load with failed MAF” (“LWFM” from here forward) table(s) are found in almost all MAF Ford Strategies. Most strategies that make use of IMRCs (Intake Manifold Runner Control – valves that restrict air entering the engine in order to increase tumble and velocity) have two LWFM tables instead of one and switch from one LWFM table to the other as the IMRCs open and close. The main purpose of the LWFM table is to estimate the amount of air going into the engine without using the MAF sensor or a MAP sensor (if present) to provide the ECM with an “emergency” fallback method of running the engine in the event the MAF sensor fails.

The LWFM table is also important for normal operation of the motor because Load from the MAF (this is “Load” – the Ford-specific calculated cylinder filling value calculated from the MAF sensor, RPM and engine displacement) is “sanity checked” against the LWFM table to determine if the MAF is providing reliable information. If there is too large of a difference between calculated Load and the LWFM table, the ECM may ignore the MAF even if it is providing valid information! This happens most commonly in forced induction situations (where load is greatly increased compared to a naturally aspirated car) but can also occur in cars with aggressive camshafts. If you are making changes to a MAF transfer function and you are not seeing any changes in engine operation, double check your LWFM table! Further, most strategies use “Anticipation logic” to predict airflow. This prediction logic is based off… Surprise… The LWFM table! Having a sane LWFM table is neccesary for the aircharge anticipation logic to work. You can disable this but it’s generally not necessary if you tune the LWFM table properly.

LWFM table is a classic example of an Alpha-N control strategy – it’s purpose is to provide a very crude estimation of airflow entering the engine when the MAF signal is absent or the ECM thinks it is unreliable. The LWFM table uses only two inputs – throttle position (aka “TP”) and RPM to determine Load. Here is a picture of a typical LWFM table: (screenshot from Binary Editor / GUFB strategy)

Here you can see the X axis is RPM and the Y axis is RELATIVE Throttle Position volts. Each cell represents the Load that will be used to calculate fueling and timing when the ECM thinks the MAF is bad. For example, idling with the throttle closed (0 volts relative) around 700 RPM the ECM will assume a Load of .1602 and make appropriate fueling and timing changes.

Here you can see the X axis is RPM and the Y axis is RELATIVE Throttle Position volts. Each cell represents the Load that will be used to calculate fueling and timing when the ECM thinks the MAF is bad. For example, idling with the throttle closed (0 volts relative) around 700 RPM the ECM will assume a Load of .1602 and make appropriate fueling and timing changes.

The importance of the LWFM table varies considerably from strategy to strategy. A rule of thumb is that the newer of an ECM you are using the more picky it will be able the LWFM table. Fox Body and most early EECV (pre-99) are fairly tolerant of inappropriate LWFM tables where 99+ ECMs are generally much, much, much more picky.

Tuning the LWFM Table

Tuning the LWFM table is pretty simple:

First, set the Aircharge WOT multiplier, Anticipation logic scalars, etc. to make the ECM as tolerant of a bad failed MAF table as possible

Second, GUESS! Yes, guess. Enter values that you think are sane for the setup, starting with the stock LWFM table as a guideline. A few examples:

- If you put in aggressive cams, decrease the LWFM table at low RPMs and throttle angles while increasing it at higher RPMs and throttle angles.

- If adding a positive displacement supercharger (roots, twin screw) multiply the whole LWFM table by approximately the highest pressure ratio you will see.

- If you add a centrifugal blower, multiply a column of the LWFM table by the pressure ratio you achieve at a given RPM

Third, drive around and log throttle position (TP Relative), RPM, Load. Compare the Load values you log with the LWFM table. Start changing entries in the table so they get closer to the load you really see at given TP and RPM conditions.

Note: Turbo cars present a very big challenge to this strategy due to the amount load can vary with throttle position due to spool time. This is a very tricky case and often the only solution is to try and maximize allowed error before the LWFM table becomes active and also disable Aircharge Anticipation and other functions dependent on the LWFM table.

BURN1+F2A+F2E: Reading Ford ECMs

Requirements

There are two products that we sell that can read the program in a factory ECM:

BURN1/BURN2 with a F2A and F2E – This setup can be used to read ECMs on the bench. ECM does not need to be powered.

QuarterHorse – This setup requires the ECM to be powered either by a vehicle’s battery or a 12V bench power supply.

Reading with BURN2+F2A+F2E

- Start with all cables disconnected (F2A,F2E,USB,etc.)

- Connect the F2E to the F2A

- Put the F2A in the BURN1/BURN2

- Connect the Burn1-2/F2A/F2E Assembly to your ECM. Make sure your ECM is powered off if it is in the vehicle

- Connect the USB from the BURN2 to the PC

- Start Flash n Burn Software on the PC

- Choose appropriate settings for the Supported chip type based on the ECM type: J3 Ford EEC-IV Reader or J3 Ford EEC-V Reader

- Choose appropriate settings based on the number of banks used:

- 56k EEC-IV = 032000 start 03FFFF end

- 64k EEC-IV = 030000 start 03FFFF end

- 2-bank EEC-V = 010000 start 02FFFF end

- 4 bank EEC-V = 000000 start 03FFFF end

- Click “Save buffer to file” and choose a filename.

Reading with QuarterHorse

At the time of writing (Aug5-2010) Binary Editor is the only software that supports this feature of the QH reliably. Select “Read PCM” from within the software.

Ford Tuning: Getting Started with Moates Hardware

Chapter 1: Introduction, Overview and Summary

Questions you may have coming in:

- How do I determine what is needed? Keep reading!

- What vehicles are compatible? Hardware will work with all 2004 and older Ford vehicles with a J3 port, depending on software support.

- What are the capabilities of Moates hardware? Realtime tuning, logging live data, burning chips, switching between multiple programs

- What hardware and software options are available, and at what cost? Keep reading!

- How do I learn to tune EEC? What learning resources are available? Keep reading! We’ll provide references.

Vehicle Compatibility

- Hardware is compatible with all year/model Ford vehicles that have a J3 port. This generally covers 86-2004 model years.

- If you already have a binary file (bin) or hex file (hex) that is tuned for your vehicle. you can use one of our chips.

- If you need to make changes (tune) to get your vehicle where you want it, you are limited by software support.

- Some ECMs are simply not supported in software that works with our hardware because of lack of definition information.

- It’s important to check for software support before purchase. If you have an uncommon vehicle (for example, a 1995 Festiva) you may be out of luck with our products.

- We need certain information to tell if your vehicle is supported. (click) Email us to check before purchase!

Overview of Tuning Process

- Determine your target vehicle boxcode and strategy.

- The Boxcode is typically a 3 or 4-digit letter/number code on the EEC computer. ( ‘A9L’ or ‘T4M0′ for example) This represents a calibration for a particular engine/transmission using a particular strategy.

- A Strategy is the set of procedures that the ECM follows to run an engine. Combined with a calbration, this determines how the engine will operate.

- The strategy will determine things like whether a MAF or MAP sensor is used, how spark and fuel are calculated, how idle is controlled, etc.

- Each strategy needs a definition (or ‘def’) to work. The definition tells the software how to interpret the binary and display it in a format you can understand with tables and real-world values.

- For instance, the A9L boxcode, belongs to the GUFB strategy. The A3M boxcode also belongs to the GUFB strategy. You can change a bunch of parameters on a A3M computer and have it run 100% identical to a A9L computer.

- Review your software options in terms of availability.

- First: figure out which software supports your box code. Support varies from package to package. Check with each software vendor for the most up-to-date supported options.

- Next: download software and install it. You can check out the interface and features at this time without paying for anything.

- Finally: After you have found a software package with an interface that you like which supports your strategy, go to our web store to purchase. You will need to have already installed software prior to purchasing in order to provide us with information to license it.

- Determine your tuning needs to guide your purchases.

- Do you just need to burn chips?

- Do you want to be able to make changes while the vehicle is running? (emulation)

- Do you want to be able to log vehicle parameters while the engine is running? (datalogging)

- Do you want a more accurate measure of the air/fuel mixture? (buy a wideband)

- Decide what capabilities you need and then purchase hardware as appropriate.

- Install hardware.

- Clean that J3 port PROPERLY!

- To clean the J3 port, you generally must remove the case from the ECM, gently rub the J3 port with Scotchbrite or a mildly abrasive kitchen scrubber. (‘mildly’ is important – you do NOT want to rub hard enough to remove the copper traces from the circuit board!) A final clean with brake clean, starting fluid or another mild solvent doesn’t hurt. A properly cleaned J3 port will have a very, very slight crosshatch visible on the ‘fingers’ of the connector.

- Golden rule: ALWAYS TAKE THE KEYS OUT OF THE IGNITION (CAR OFF!!!) WHEN INSERTING OR REMOVING THINGS ON THE J3 PORT. Failure to do so can result in a fried ECM, fried chip/QuarterHorse or both.

- Install USB drivers

- The same USB drivers are used for all Ford products

- USB driver is a free download from the webstore, it comes with config instructions. (download)

- If you need more visual directions, there is an install guide available on the Moates support site.

- If you have trouble with the install, there is troubleshooting guide available on the Moates support site.

- Setup software and perform initial configuration

- Establish communications, check settings – this procedure will vary depending on software package you are using.

- Select the appropriate strategy for your box code and load any appropriate definition files.

- Program hardware with a calibration to serve as a starting point. A stock tune with a few key parameters modified to suit the vehicle at hand is great. You’re just looking for something good enough to get the car to fire and (hopefully) idle.

- If you are datalogging, select and configure datalogging payload matrix (PIDs) – i.e. what you’re interested in monitoring.

- Gather performance data, analyze it, and make changes toward an optimized result.

- Parameters are gradually adjusted to achieve desired targets.

- This is an iterative process, where adjustments are made and the results are evaluated followed by further adjustments.

- Please see our subsequent chapters on Ford Tuning (available separately).

- Basic Tuning Techniques and Common Examples

- Advanced Tuning and Tricky Combinations

Chapter 2: Hardware Selection and Installation

Several types of hardware are available and needed depending on desired functionality.

Laptop PC

- Windows XP/Vista/7 are all compatible with the Ford tuning software.

- Something 5 years old or newer is recommended (no old 486 machines!).

- Internet access is recommended to facilitate licensing and software installations.

- USB ports (at least 1) are required. All needed cables are included with the hardware.

- If logging wideband, a serial-to-USB converter may be needed. ($37 on our webstore – link)

F3 Chip modules

- These modules install onto the J3 port of the EEC box.

- One per vehicle, $60 per unit – link.

- J3 port MUST be thoroughly cleaned, both sides, before installation!

- Disassemble case, scrape off coating with non-metallic scraper or fingernail.

- Clean both sides with Scotchbrite, not sandpaper.

- Don’t be too rough, just polish it to a nice crosshatch, not down to the copper.

- Clean with paper towel and alcohol or toluene.

- Two-position switch capable with user-added toggle. Directions for switching are on support site. (link)

- Reprogrammable many times using Jaybird.

Jaybird mini-USB chip reader/writer

- Small size, low cost, $75 – link.

- Allows reading and writing of the F3 modules.

- No datalogging or emulation with the Jaybird. No EEC box reading. Most basic chip programmer available.

Quarterhorse Realtime Emulator and Datalogger

- Hardware unit is $249 – link. All cabling is included, along with ferrite shields and USB bulkhead connections.

- Optional rotary switch ($30 – link) can be used to select from several different programs on the device, switching on-the-fly. Works for EECIV ONLY.

- Fits onto J3 port like a chip module - port MUST be clean as with F3 modules.

- On some early EEC boxes, several components will need to be gently bent out of the way for clearance during installation.

- The Quarterhorse is an integrated unit that can do several things:

- Realtime Emulation

- Changes in the calibration take effect immediately while engine is running.

- No disturbance in engine operation or communications.

- Changes in software are synchronized on the Quarterhorse.

- Datalogging

- Requires special definition file with ‘patch code’ written for the QuarterHorse, allowing RAM on the EEC to be shadowed onto the Quarterhorse.

- Unprecedented access to variables and sensor values through the QuarterHorse without additional datalogging hardware.

- Logging rates in excess of 5 kHz possible. Most software logs around 20 Hz, which is great for tuning.

- EEC Reading

- EEC must be installed and powered in-vehicle with QH installed.

- You can read the tune from the EEC box and save it to file.

- This can be done with a stock EEC to acquire the base calibration.

- You will be able to harvest the active calibration that has been programmed with a flash programmer this way.

- Realtime Emulation

Burn2 with F2A and F2E adapters

- The Burn2 ($85 – link) is a general purpose chip programmer that can be used for many different devices.

- When used with the F2A adapter ($10 – link), it can be used to read/write F3 modules.

- If the F2E adapter is added (another $10 – link), you will be able to read EEC boxes.

- No emulation or datalogging – this is a simple chip programmer only.

- This hardware combination is best suited for people that plan to tune vehicles from many different manufacturers. If you plan on tuning exclusively Fords, consider the Jaybird as a less expensive alternative.

F8 chip module with Destiny programmer

- No emulation or datalogging – this is a simple chip with switchable tunes.

- Available exclusively through our distributor DP Tuner

- The $165 F8 module holds 8 switchable tunes and can be reprogrammed in-vehicle without removing the chip from the EEC!

- The $150 Destiny programmer is used with a 4-pin switch cable while F8 module stays installed on EEC.

- Once programmed, the $30 rotary switch can optionally be connected as a calibration selector.

Wideband O2 Sensor and Controller

- Used to sense your engine’s Air-Fuel ratio through exhaust gas analysis.

- Units such as the Innovate DB-Red LC1 Gauge Kit /w/ O2 ($209 – link) are very affordable.

- Software (discussed separately here) supports direct logging of the Innovate device data using a serial interface. This is the preferred method of logging wideband data because it avoids all the pitfalls of using analog signals.

- Analog outputs from the wideband (such as the LC1) can be connected directly to the EEC in some cases (unused EGR pin on A9L for example).

- Wideband O2 readings critical for tuning fueling parameters.

Chapter 3: Software Selection, Installation, and Licensing

Several different software packages currently work with our hardware. Cost varies considerably considerably from package to package along with capabilities. Each software package also has its own unique flavor of interface – you will probably like one better than another. Luckily, you can download and check them out prior to purchase. Also remember that support for various box codes / strategies varies considerably from package to package. It is important to investigate not just whether there is ANY support for a particular strategy but whether the items you require to tune your vehicle are supported – definition files vary considerably from software to software. Fortunately, the availability of ‘trial’ versions makes it possible to ensure you to find a software package that fits your needs without having to purchase each one.

Binary Editor ( http://www.eecanalyzer.net )

- Written by Clint Garrity.

- Currently has the largest user base.

- Cost is $80 for the base application which is registered to a specific PC.

- Includes many of the most common and popular definitions (GUFB, etc) with no additional cost. ( this list has almost all the “free” definitions along with some pay defs )

- Other ‘premium’ encoded definitions available at extra cost ($50-150+) from the definition author.

- Tends to benefit from a faster/newer laptop. Code is a bit heavy, so older PCs are taxed. Think 2Ghz P4 / 512Mb ram realistic minimum.

- Includes EEC reading, chip reading and burning, datalogging, and emulation capabilities when used with the appropriate hardware.

- Also includes logging for wideband (Innovate, PLX, etc).

- Also includes optional support for standalone dataloggers, J2534 interfaces.

- Companion software EEC Analyzer is available for an additional $50. Not necessary, but it helps with data interpretation.

- Licensing occurs after you install the software from the available downloads, through a menu item within the BE and EA software programs.

- Both BE and EA licenses can be purchased from the webstore with information from the program. See webstore product page for further instructions.

EEC Editor ( http://www.moates.net )

- Written by Paul Booth.

- Fairly lightweight software – does not require a very fast PC to work well.

- Cost ranges from $20-65 for each strategy depending on options.

- EEC-IV is $20 for editing DEF (emulation and chip burning) plus $25 for datalogging (DLM) .

- EEC-V is $10 more ($30+$35).

- In order to have a comprehensive tuning solution for a typical fox body Mustang, you would need to order the GUFB def ($20) and the GUFB DLM ($25) along with a QuarterHorse. This would allow you to tune any number of vehicles using the A9L, A3M, etc. processor codes. You can also burn chips with the Jaybird/BURN2+F2A for any strategies you have purchased.

- Includes logging for Innovate Wideband (LC1, LM1, etc) at no additional charge.

- List of available supported strategies is listed on the webstore.

TunerPro RT v5 ( http://www.tunerpro.net )

- Written by Mark Mansur.

- Software license is optional (nag screen) but encouraged for $30.

- Editing portion of software *extremely* lightweight – can run well on older PCs. Parts of logging engine considerably more demanding.

- Many definitions are available for editing only, see Tunerpro.net and our website for details.

- Editing, chip burning and emulation are supported by TPRT V4 and TPRT V5.

- Datalogging using the QuarterHorse is supported by TunerPro RT V5 via new the ADX format. See here for updated definitions.

- QuarterHorse vehicle support is very limited compared to other software, but some of the most popular ones (GUFB CBAZA etc) are well-developed and available at time of writing (December 2010)

Flash & Burn Interface ( Moates/TunerPro )

- This is a low-level utility for reading and writing F3 chip modules using Jaybird or BURN1/BURN2 + F2A

- Capable of reading EEC boxes using BURN2+F2A+F2E. Does not work with QuarterHorse

- If you have a raw binary file ( bin ) you can use Flash n Burn to program a F3 chip module

- No cost, can be downloaded from the webstore.

F8 Destiny Utility ( http://www.moates.net )

- For use with a Destiny and F8 multi-position in-situ chip module.

- Allows easy management of stacks of tunes on the module with PC-based selection.

- No cost, can be downloaded from the webstore.

USB Driver ( Moates.net / FTDI )

- Needed to allow PC to communicate with the USB hardware (Quarterhorse, Jaybird, BURN2, etc).

- In many cases, working drivers will be detected by Windows via plug n play.

- If you need more visual directions, there is an install guide available on the Moates support site.

- If you have trouble with the install, there is troubleshooting guide available on the Moates support site.

Chapter 4: Suggested Techniques for Effective Calibration of EEC Systems

Vehicle Inspection and Preparation

- CRITICAL part of the tuning process. Start here, really. If you fail here, you will never succeed.

- Several areas of the vehicle should always be analyzed before you begin the effort.

- Smoking – learn to identify fuel (black) vs. oil (grey-blue) vs. coolant (white/sweet smelling). You cannot fix oil smoke or coolant smoke with a tune.

- Compression – you should have all cylinders within 10% compression of each other. If smoking, damage to old spark plugs or general appearances make you suspicious of the motor’s health, check it before you start. It’s a lot easier to deal with a motor with poor compression BEFORE you beat the snot out of it in the course of tuning it. Many people skip this but it is something to think about because a motor that is already hurt is very likely to blow up or experience a catastrophic failure during tuning.

- Check base timing, adjust as needed. (all vehicles with a distributor)

- Evaluate TPS voltage. Minimum/maximum values should be within acceptable limits. Check for reversed wires – voltage should increase as throttle opens.

- Look at MAF intake routing, make sure there are no obvious vacuum / intake leaks between the MAF and the intake valves. Think cracked/split/loose hoses, bad gaskets, open ports, dry rotted couplers, hoses connected both before and after the MAF, …

- O2 sensors should be operational without any exhaust leaks before the sensors. For some reason, cut and soldered “extensions” for long tube headers often cause problems. Plug and play extenders are *highly* recommended. If you know that you do not have proper stock O2 sensors, REMEMBER TO TURN OFF O2 FEEDBACK!!!

- If you are using a wideband sensor, you need to make sure there are no exhaust leaks before the wideband. Flex tubing, poor joints between headers- midpipes and cracks in tubing can all create havoc.

- If applicable, pay attention to which bank the wideband is installed in – bank-bank differences can be a powerful diagnostic tool. Pay attention to how far the wideband is from the engine’s exhaust ports – there is always some lag between combustion events and measurement. When things are changing quickly, this is critical.

- Widebands need calibrated periodically, generally in free air. Wideband sensors need replaced periodically. Leaded fuel kills them very quickly. Proper care and feeding of widebands is crucial to their effectiveness.

- Be aware of catalytic converters. Always tap them (GENTLY) and listen for suspicious noises that would indicate a catalytic converter that is degrading. Clogged cats can rob literally hundreds of horsepower. It is possible to place a wideband sensor AFTER a catalytic converter but remember that the cat will very slightly skew readings.

- Make sure you have enough fuel pump and injectors for the power level you are looking for. For a V8, “Injector size in #/hr * 14 = max hp” is a crude rule of thumb. There are tons of injector calculators to be found if you want a better idea.

- Ensure that fuel pressure is sane. 40psi with no vacuum reference is generally about where most OEM regulators are set. You should be able to see a difference in fuel pressure between key-on-engine-off, idle and blipping the throttle. Fuel pressure should be lowest when vacuum is highest. Fuel pressure should increase when you blip the throttle as manifold pressure increases.

- You need a MAF capable of metering enough air for your power goals. There are ways to increase the metering capacity of a given meter, but tuning that properly is an advanced topic. Keeping it simple: get a meter that can handle your airflow needs.

- You need a functioning alternator and battery. Battery voltage plays a role in crucial things like injector opening time and coil charge duration. If your charging system is not functioning correctly, your tune may drastically change if/when you fix it. Rule of thumb: if your battery voltage ever drops below 13 volts with the motor running, you will run into trouble.

- On a similar note, underdrive and overdrive pulleys can cause real issues. Pay attention if you see them.

- Check for emissions hardware ( purge, smog pump, EGR, etc. ) that is missing. In many cases these items can be disabled but you need to pay attention to what is present compared to what the ECM expects.

- Basic maintenance should not be overlooked. If it is important for a “normal” car it is twice as important in a performance application.

- Spark plugs: correct heat range, appropriate gap, not fouled. Consider power level, fuel and ignition system. AVOID PLATINUM PLUGS FOR PERFORMANCE APPLICATIONS!!! Copper or iridium will serve you much better.

- Plug wires: no cracks/arcing, properly crimped ends, appropriate length so there isn’t too much tension

- Firing order: firing order is determined by the camshaft (mostly) not the block or computer.

- Spark boxes: great for distributor engines, unneeded/problematic for mod motors

- Coil packs: Coil-per-cylinder (99-04 generally) applications like ***OEM*** coils best. (according to Dave B.) MSD, Accel, Granatelli, … are all cause for concern especially with boost.

- Oil and coolant: always check fluids before starting. Quick check, potentially horrible consequences if low/out.

- Fans / overheating: it is always a good idea to check that radiator fans work. A car that overheats cannot be tuned.

- Belts and Idlers: All serpentine belts must be in good shape. Cracks, missing ribs, etc. will all cause problems. Any idler pulleys must spin freely.

- Tension: Belt Tensioner should not be extended fully with the engine off. Adjust belt length so that tensioner is in the lower third of its adjustment range with the motor off. (i.e. it can move 2/3 through its range to increase belt tension – it should be mostly compressed when motor idle) This is particularly important for supercharged applications.

- Fuel filter: Fords are *horrible* about clogging fuel filters. Especially if the car has been sitting for any significant period of time, change the fuel filter. Motorcraft/OEM filters seem to hold up better than many cheap aftermarket ones.

- Fuel age and type: Gasoline degrades with time. Do not expect fuel that is more than a month or two old to be of the same quality as fresh gas. Be particularly careful with heavily oxygenated fuels (i.e. VP Q16) and alcohols (ethanol, methanol, E85, etc.) in contact with fuel system components for large periods of time.

- Clean air filter and MAF. Oiled filters generally cause MAFs to get dirty. Clean MAFs only after they have had a long time to cool – hot MAF+liquid=death. Clean *GENTLY* with brake clean, starting fluid, or other organic solvents.

- Remember, you can’t fix mechanical or electrical issues by reprogramming the ECM!!! The results you achieve with tuning will only be as good as the material you start working with. Garbage in, garbage out.

Datalogging: What’s important and what does it mean? What should we be interested in? What to select?

- There are certain sensors that you will almost always want to keep an eye on because they are critical to engine operation:

- RPM – how fast the motor is spinning

- MAFV / MAF counts – a “raw” value representing the reading from the MAF sensor

- Airflow – a value calculated by the ECM from the raw sensor MAF voltage that represents how much air is being ingested by the engine. This is often represented in some form of “real world” value, like Kg/hr or Lbs/min

- Load – from 94-2004 “Load” is the main factor involved in determining spark advance.

- Spark Advance – when the ECM is commanding sparks to be fired.

- TPS – Throttle Position Sensor. How far open the throttle is, i.e. how hard you’re pressing the gas pedal

- ECT – Engine Coolant Temperature(how hot or cold coolant flowing through the engine is)

- IAT – Intake Air Temperature (how hot or cold air entering the engine is)

- Depending on what you are trying to do, there are other items you may want to pay attention to as well.

- Injector Pulsewidth – How long the injectors open. This can be useful both for “sanity checking” and to ensure you do not run out of injector – there is only a fixed time available at a given RPM to fire injectors.

- HEGO1/2 – Heated Exhaust Gas Oxygen sensor. Measures the presence or absence of oxygen in the exhaust in order to try to determine whether the motor is running rich or lean. Watching the raw HEGO voltages can give you some kind of very basic indication of fueling. These sensors experience a large change in voltage in a very small area centered around a stoichiometric mixture ( 1.0 lambda or about 14.7:1 Air-Fuel Ratio or AFR)

- STFTs – Short Term Fuel Trims. These are IMMEDIATE changes the ECM makes in response to HEGO readings in order to steer the air-fuel mixture towards desired targets. If your EEC uses STFTs effectively (i.e. all modular motors) then these are generally more effective as a tuning tool than looking at raw O2 voltages.

- LTFTs – Long Term Fuel Trims. These are the long term difference between programmed values and target values. Think of them as the average of STFTs over a long time. If your EEC uses LTFTs effectively (i.e. all modular motors) then these are one of the most effective pieces of data provided by the stock computer for tuning fueling.

- WBO2 – Wideband Oxygen meters can measure a much wider range of rich-lean conditions than standard HEGOs. Having wideband data is often preferable to HEGO/STFT/LTFT. In many cases (i.e. 86-95 in my opinion) it is often easier to disable closed loop operation/the O2 sensors completely and tune the car exclusively using a wideband.

- ISC Integrator (‘integrator’) – this represents the difference between how much air the EEC is using to hold and idle versus how much it is commanded to hold in the tune. Critical for proper tuning of larger camshafts and larger displacement engines.

- Boost/MAP/Pressure – Although MAF systems do not differentiate between boost and vacuum, it is often very handy for sanity and safety to have an idea of how much pressure there is in the intake manifold. For positive displacement blowers (roots, TVS, twin-screw) make sure you take pressure readings AFTER the blower on the lower plenum.

- Pressure drop across injectors / FPDM duty cycle – most 99-04 cars control fuel pressure electronically. These values are critical to a properly operating fuel system on these vehicles.

Recalibration: Modifying Parameters and Values to Achieve a Target

- First step: decide on target operating parameters for the engine

- This may seem obvious, but something as simple as “make the most power” or “improve fuel economy” isn’t going to be be enough.

- Second step: take a general goal like “make the most power” and decide on appropriate engine conditions to achieve that goal.

- If you read these rules of thumb and say “this isn’t right for my engine” – GREAT. You already know more than the audience these rules are aimed at.

- If in doubt, “0.8 is great” – blatant simplicity. Quoted me to once by someone who did OEM calibrations for Honda for a living. It is very difficult to break anything due to fueling from running a vehicle at 0.8 lambda (about 11.6:1 AFR Gasoline)

- 1.0 Lambda represents a stoichiometric mixture – exactly enough oxygen is present in the air to burn all the fuel supplied. This is normally the best mixture for minimizing emissions.

- Most vehicles make best power around 0.85 to 0.88 lambda (12.3 – 12.7 AFR Gasoline) – slightly richer than stoich

- Most vehicles achieve best fuel economy at around 1.05 to 1.1 lambda ( 15.2 to 16.0 AFR gasoline)

- Most vehicles need more ignition advance as RPM increases

- Most vehicles need more ignition advance under cruising/low-throttle conditions than WOT

- Knock is most likely close to peak torque, at high loads/low RPMs or at peak horsepower

- Next step: Get familiar with the strategy your vehicle uses. Fueling, timing, idle, open-closed loop and just about everything else vary considerably from one strategy to another. Being familiar with the strategy your ECM uses will help you figure out which tables to modify to acheive the results you seek.

- eectuning.org is a good place to learn more.

- the ‘Education’ section of moates.net is another good place to get information

- After you figure out where to look: set up what you can based on what you already know

- Setup Engine Displacement / displacement of one cylinder

- Setup injector size

- Setup a reasonable rev limiter based on what you know of bottom end and valvetrain

- Setup a reasonable (perhaps a little high to start) value for target idle

- Setup a reasonable base calibration for MAF sensor. If sensor came with a calibration sheet, this would be great time to use it.

- Setup a reasonable target air fuel while in open loop

- Setup a reasonable timing map. A stock timing map adjusted for mods is always a good place to start.

- Setup a reasonable pattern from switching from closed loop to open loop.

- Enable or disable hardware such as O2 sensors, EGR, Purge/Evap, automatic trans

- If you take your time to create a sane starting point before you turn the key on you will save yourself countless hours of time!

- Finally: Start your engines (and your datalogger) and make final adjustments

- Are air fuels not matching what you command in open loop?

- Three pieces of the fueling puzzle: MAF transfer, Injector slopes(size), Injector offset (battery compensation – latency)

- How do you tell what is going on? STFTs, LTFTs (if O2s are enabled) combined with a wideband. STFTs/LTFTs are great while O2s are active – i.e. part throttle

- Leanest at idle, small pulsewidths but perfect at WOT/higher throttle -> increase battery offset

- Lean – rich – lean patches as you gradually increase throttle -> wrong shape of MAF curve. systematically tune it

- Entire range of engine operation uniformly off from commanded values -> either injector slopes (size) or entire MAF transfer function is off. Let load determine which one to multiply/divide in order to fix things

- Idle issues?

- Make sure your MAF transfer table, injector slopes and injector offset are sane before trying to fine tune idle!

- Follow the integrator – a good place to start is to add the integrator (or subtract if it is negative) from the Neutral Idle Air table (in neutral) or Drive Idle Air table (if in Drive for automatic cars)

- Performance

- ALWAYS TUNE FUELING FIRST BEFORE TACKLING TIMING! You are *much* more likely to break your engine if your mixture is wrong. As long as your timing is good enough to light the mix, you can tune fueling adequately.

- Tuning timing without a dyno is hard. Accelerometers and a dragstrip can provide crude but repeatable feedback.

- Are air fuels not matching what you command in open loop?

Data Analysis and Evaluation

- Once captured, the operational data can be analyzed and used to guide calibration effort.

(More to come!)

(below this line is draft / coming soon as of 2010-11-30)

Chapter 4: Software/Hardware Initial Configuration with Tuning Session Start-Up Examples

- Physical installation of hardware is shown in more detail from Chapter 1 overview.

- F3

- Jaybird

- Quarterhorse

- F8/destiny and switch

- Wideband

- Installation, licensing, initial configuration, and detailed hardware synchronization procedures for each software are explained and examples detailed. Initial basic calibration load-up for different hardware, as well as basic payload creation for datalogging, are explained and illustrated for each.

- USB Driver

- BE/EA

- EEC Editor

- TunerPro RTv5

- Flash & Burn

- F8/Destiny Utility

- Data Analysis and Evaluation

- Once captured, the operational data can be analyzed and used to guide calibration effort.